|

Want notifications for new Blog Posts, White Papers, Case Studies & Webinars? |

Join Our Community

|

Time is Right for Time-Sensitive Networking

In a world where costs are constantly rising, supply chains have still not recovered from the disruptions of the COVID-19 pandemic, and skilled employees are in critically short supply, manufacturers are faced with the challenge of getting more productivity and profits out of their factories. While the Internet of Things has been talked about for years, it seems the idea of creating smart factories is one whose time has come.

The vision of the factory of tomorrow is one of machines, production lines, plants and entire supply chains that communicate with each other, in concert with IT systems, to enhance productivity, efficiency and flexibility.

Suppliers of automation components and systems have been preparing for this moment for years, developing technologies that allow greater visibility into the factory floor. Their efforts are enabling data from machines and production lines to be collected and analyzed so that workers can understand what is happening and why, and what to do to make operations more productive.

The first step on the road to smarter manufacturing is convergence. That means gathering operational data from machines and production lines and sending it to information technology systems to analyze.

This IT/OT convergence is now a reality for the industrial world. It allows manufacturers to make smarter decisions about equipment utilization for optimized performance and product quality, to streamline maintenance activities by predicting potential equipment failure ahead of time using condition-based monitoring, and to schedule repairs to minimize downtime.

The industrial Ethernet continues to evolve to support the terabytes of data that can be gathered from the multitude of disparate devices and networks in the OT world. The importance of connectivity and being able to gather data is the foundation for the digital transformation journey.

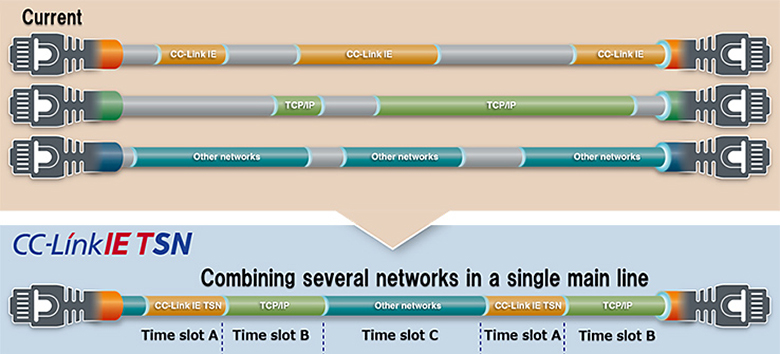

One of the key technologies for this evolution is Time-Sensitive Networking (TSN). It was specifically developed to enhance standard Ethernet to provide the key functionality, performance and reliability necessary to achieve this network convergence for a digital transformation. The ability to run multiple industrial Ethernet protocols along with IT traffic (called convergence) on the same physical wire can be realized with TSN technology and, more important, allow critical control applications to run in parallel and seamlessly with generic configuration, programming and diagnostic applications.

Convergence provides the infrastructure to merge different traffic types onto a single network without affecting the performance of shop floor communications. This is fundamental to sharing operational insights and hence increasing process transparency across an enterprise, which can then be used to derive insights to optimize manufacturing facilities and entire organizations. TSN extends standard Ethernet to be interoperable and compatible with already installed Ethernet devices and networks.

There are four benefits to a converged network:

- Control devices that have previously been isolated to separated control networks, which had been required to ensure deterministic performance, can now be addressable and accessible to other applications for use in advanced analytics and digital twins.

- Devices are becoming smarter and more complex, requiring management, which can now be accomplished over one connection.

- Architectures are simplified through the use of one network, improving deployment and troubleshooting, and

- Costs are reduced through the simplification of architectures.

All automation suppliers and system integrators are expected to deliver TSN-compatible products. By doing so they can help their customers to create the factories of the future while enhancing their own competitiveness in a fast-growing market.

One communication protocol that is now delivering the benefits of Ethernet with TSN is called CC-Link IE TSN, managed by CLPA – the CC-Link Partner Association (https://am.cc-link.org/en/index). CLPA is affiliated with Mitsubishi Electric's e-F@ctory Alliance, a network of more than 450 technology partners, solution experts and suppliers around the world who are working together to enable their customers to operate more intelligent and productive factories and facilities.

You can learn more about Mitsubishi Electric and their industry partners at https://us.mitsubishielectric.com/fa/en/solutions/efactory/alliance-partners

Want to be notified regarding new material such as Blog Posts, White Papers, Case Studies and Webinars?

Join Our Community