|

Want notifications for new Blog Posts, White Papers, Case Studies & Webinars? |

Join Our Community

|

Time Sensitive Networking Advances Smart Factories

Since its global introduction in late 2018, CC-Link IE TSN has brought the benefits of time sensitive networking (TSN) to multiple industries. As the first open industrial Ethernet technology to combine TSN with gigabit bandwidth, CC-Link IE TSN has received strong vendor support and enthusiastic market response.

While acceptance has been particularly strong in Asia, where CC-Link was first developed, it's now winning growing favor in North America among machine builders and manufacturers. Efforts are also underway to educate the European market about CC-Link IE TSN and its benefits in supporting smart manufacturing.

More than 50 Asian manufacturers are now using CC-Link IE TSN in multiple industries, from automotive, lithium battery and semiconductor manufacturing, to food and beverage processing, consumer packaged goods and electronics.

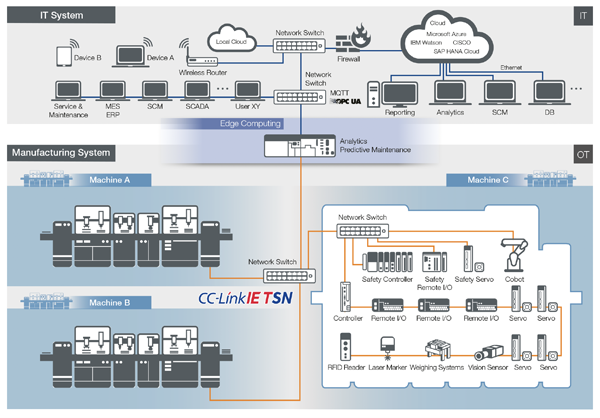

CC-Link's TSN technology meets the needs of most applications, delivering comprehensive solutions for connecting factory floor devices such as PLCs, motion control systems, VFDs, I/O systems, HMIs, infrastructure and engineering tools.

Key benefits include the ability to bring together the multiple network architectures used on most factory floors and in enterprise level networks to improve OT/IT integration. This convergence enables optimized processes through increased transparency, delivering higher productivity. CC-Link IE TSN also helps address the challenges of Industry 4.0 through its gigabit bandwidth infrastructure, ensuring the successful convergence of all types of traffic.

Why convergence?

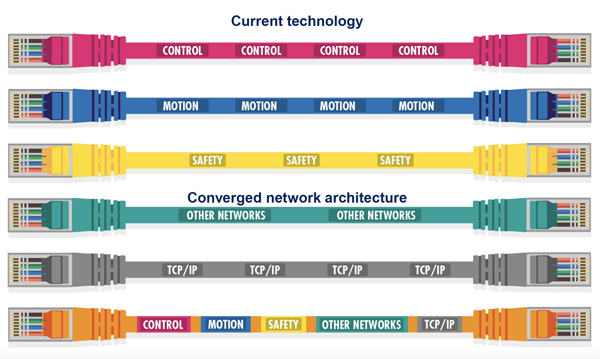

A technology that can bring together these multiple network architectures goes a long way toward simplifying industrial communications. Instead of being confined to traditional siloes for different functions, device traffic can now be connected on one network to communicate with both factory and IT systems, enabling more comprehensive data gathering and data analysis.

CC-Link IE TSN enables device traffic for I/O, motion and safety, plus devices such as bar code readers and printers, to transit on the same network. With multiple protocols co-existing on a single network, the convergence of IT and OT can be achieved.

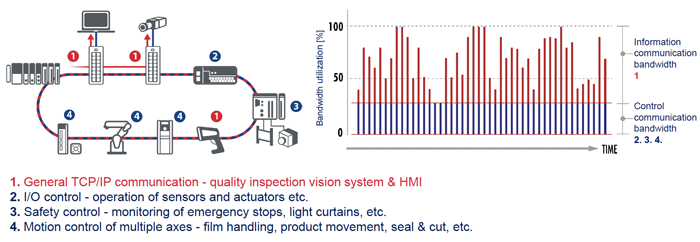

The diagrams below illustrate how this operational technology network convergence can be achieved on a packaging machine so that different devices and traffic can share a single network. One section of the bandwidth is set aside for information communication and the other for control communication.

This enables the creation of a single transparent architecture from the sensor level to the cloud.

How TSN can transform operations

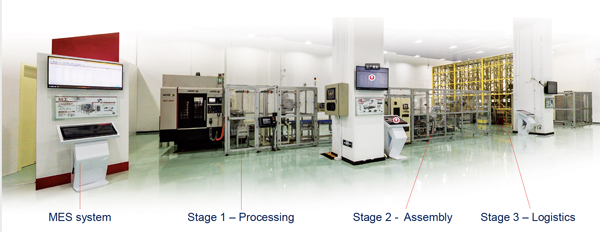

The mass customization of picture frame manufacturing at ITEI in China provides a before and after look at how CC-Link IE TSN has transformed their operations.

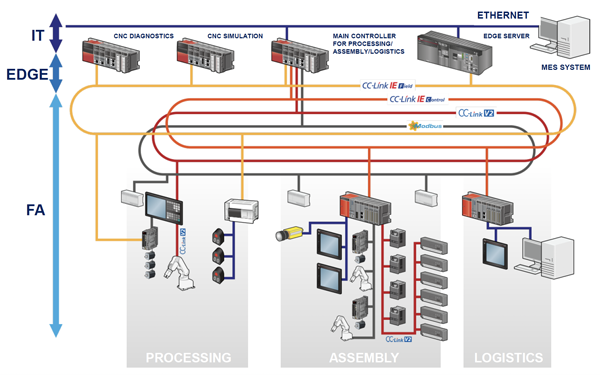

Network Architecture Evolution – Original State

Challenge: Multiple networks (field & industrial Ethernet) caused high complexity and lack of transparency

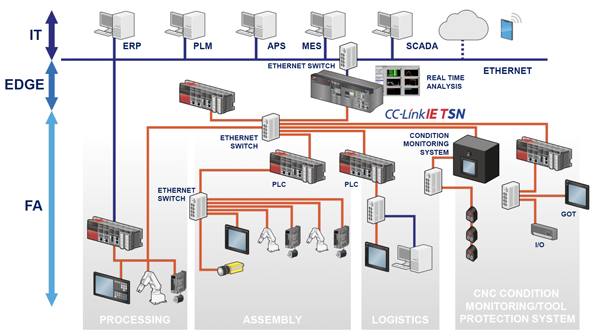

Network Architecture Evolution – Final State

Benefits delivered by TSN:

- Simpler network architecture/system design with one converged network

- Greater process transparency and better management and access to data from the process and for optimization instructions to it

- More productivity and 10% reduction in cycle time for robot and servo control

- Better integration of OT and IT systems, with improved collection of sensor data, accuracy of analysis and improved uptime

Other companies in different industries have experienced similar transformational gains by deploying CC-Link IE TSN.

Case Study: Shashin Kagaku, Additive Manufacturing, Japan

Challenge:

Japanese machine builder Shashin Kagaku needed to simplify machine design by combining multi-axis sub-micron motion control with UV laser and other machine functions on one network. The goal was to achieve significant productivity gains.

How TSN Delivered:

- OT convergence enabled tight integration with the system I/O, UV laser and multi-axis, high-precision motion control system on the same network.

- Simplified system design meant less wiring, reduced construction time, shorter delivery time, reduced system cost and a more competitive product.

- Gigabit bandwidth contributed to about 10 times faster component production time than previous models.

Case Study: Orisol, Footwear Manufacturing, Taiwan

Challenge:

Taiwanese footwear maker Orisol wanted to achieve integration of a smart shoe manufacturing system focused on digitalization. The goals were to:

- Simplify machine design while delivering significant productivity gains

- Precise process control for successful bonding of the upper to sole assembly on the flash activation machine

How TSN Delivered:

- OT Convergence

- Single network architecture for machine communications between vision systems, temperature sensors, heat lamps, switches, indicators and sensors.

- Delivers necessary process responsiveness independent of environmental conditions and millisecond process synchronization between machines.

- IT/OT convergence

- Integrates multiple machines into Orisol's proprietary monitoring and remote maintenance systems.

- Gigabit bandwidth enabled 220X communication speed increase.

- Led to 7X faster process execution time, overall application speed increased 12X.

Case Study: Lithium-Ion Battery Manufacturing, China

Challenges:

- Combine highly critical electrolyte coating and film winding processes with general machine control, safety and IT system integration without compromising cell quality or machine productivity

How TSN delivered:

- OT Convergence – precise motion control of winding and lamination is combined with I/O and safety on same network with no process compromises.

- TSN & gigabit bandwidth enable microsecond synchronization of motion axes along with general machine functions.

- IT convergence – connect with AI-based maintenance systems for further process optimization.

As these examples illustrate, TSN has become a key technology for the future of industrial automation. It delivers:

- Converged network architectures for simpler networks and machine designs,

- Better OT/IT integration,

- Process optimization through increased transparency,

- Higher productivity,

- Gigabit bandwidth infrastructure capable of handling the challenges of Industry 4.0.

For over 20 years, the CC-Link Partner Association (CLPA) has been responsible for the technical development and promotion of the CC-Link family of open automation networks. In 2018 it introduced CC-Link IE TSN, which is the only open industrial Ethernet to combine TSN with gigabit Ethernet. There are now over 2,600 products using CLPA technologies and over 370 partner manufacturers, with an installed global base of more than 38 million devices.

Visit the CC-Link Partner Association website for product information, latest news, and how to become a CLPA member.

Want to be notified regarding new material such as Blog Posts, White Papers, Case Studies and Webinars?

Join Our Community