High-PrecisionTuning

Servo gain adjustment with one-touch ease

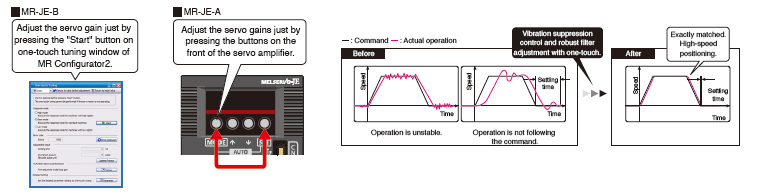

Advanced One-Touch Tuning Function

Servo gain adjustment is complete just by turning on the one-touch tuning function. With this function, machine resonance suppression

filter, advanced vibration suppression control II*, and robust filter are automatically adjusted to maximize your machine performance.

* The advanced vibration suppression control II automatically adjusts one frequency.

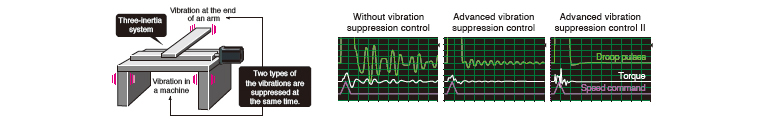

Suppress two types of low frequency vibrations at once

Advanced Vibration Suppression Control II

The advanced vibration suppression control II suppresses two types of low frequency vibrations owing to vibration suppression

algorithm which supports three-inertia system. This function is effective in suppressing residual vibration generated at the end of

an arm and in a machine, enabling a shorter settling time. Adjustment is easily performed on MR Configurator2.

Wide frequency range

Machine Resonance Suppression Filter

With advanced filter structure, applicable frequency range is

expanded to between 10 Hz and 4500 Hz. Additionally, the

number of simultaneously applicable filters is increased to

five, improving vibration suppression performance of a

machine.

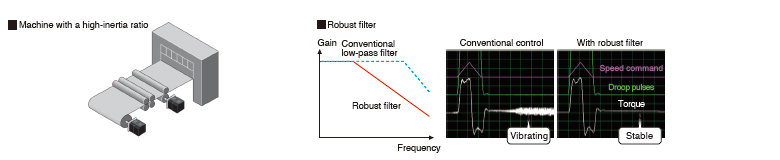

High responsivity and stability

Robust Filter

Achieving both high responsivity and stability was difficult with

the conventional control in high-inertia systems with belts and

gears such as printing and packaging machines. Now, this

function enables the high responsivity and the stability at the

same time without adjustment. The robust filter gradually

reduces the fluctuation of torque in wide frequency range and

achieves more stability as compared to the prior model.

For Changes in Power Supply Environment

Reduce machine downtime

Large Capacity Main Circuit Capacitor

The capacity of main circuit capacitor is increased by 20% as

compared to the previous model, increasing the tolerance

against instantaneous power failure. The increased tolerance

reduces machine downtime and then improves productivity.

Wide power supply voltage input range

Compatible with 1-phase 200 to 240 V AC Input

Servo amplifiers of 2 kW or smaller are compatible with power

supply voltage of 1-phase 200 V AC to 240 V AC.

* When 1-phase 200 V AC to 240 V AC power supply is used with servo amplifiers of

1 kW and 2 kW, use the servo amplifiers with 75% or less of the effective load ratio.

The servo amplifiers of 1 kW and 2 kW cannot be mounted closely when 1-phase

power is input.

Reduce undervoltage alarms

Instantaneous Power Failure Tough Drive

When an instantaneous power failure is detected, this function

allows the servo amplifier to use the electric energy charged

in the main circuit capacitor in the servo amplifier to avoid an

alarm occurrence, increasing the machine availability even

with an unstable power supply.

A Variety of Positioning Functions

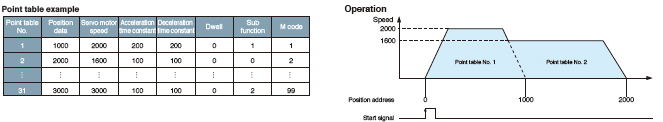

Easy to set a positioning data

Point Table Method

Setting position data (target position), servo motor speed, and acceleration/deceleration time constants in point table is as easy as

setting a parameter. Up to 31 points are settable for the point table. The positioning operation is performed with a start signal after

selecting the point table No.

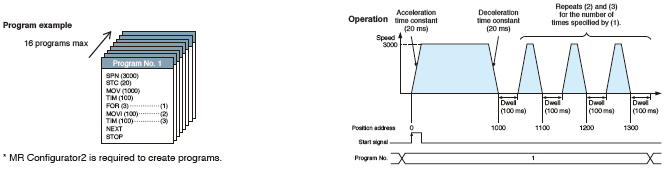

Easy operation by program

Program Method*

Create positioning programs with dedicated commands. The positioning operation is performed with a start signal after selecting

the program No. The program method enables more complex positioning operation than the point table method. Maximum of 16

programs are settable. (The total number of steps of program: 480)

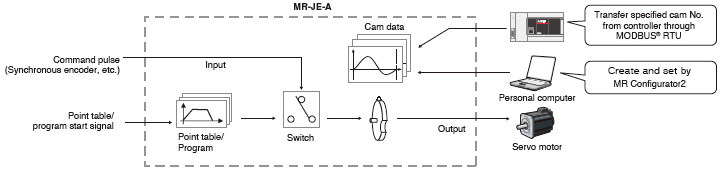

Easy to create electronic cam

Simple Cam Function

Various patterns of cam data* can be created easily by using MR Configurator2. Command pulse or point table/program start

signal can be used as input to the simple cam. The input command will be outputted to the servo motor according to the cam data.

* Cam curve can be selected from 12 types (constant speed/constant acceleration/5th curve/single hypotenuse/cycloid/distorted trapezoid/distorted sine/distorted constant speed/trapecloid/reverse trapecloid/double hypotenuse/reverse double hypotenuse). For details of simple cam function, refer to in the catalog.

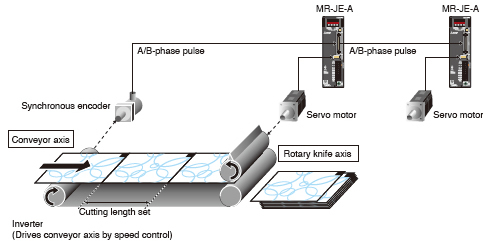

Synchronous operation by encoder signal input

Encoder Following Function/Command Pulse Input Through Function

With the encoder following function, the servo amplifier receives A/B-phase output signal from the synchronous encoder as

command pulse, and the input command will be outputted to the servo motor according to the cam data. By setting cam data that

matches with sheet length, a diameter of the rotary knife axis, and synchronous section of the sheet; a system in which the

conveyor axis and the rotary knife axis are synchronized can be configured. Up to 4 Mpulses/s of input from synchronous encoder

is compatible with the servo amplifier.

The command pulse input through function allows the first axis to output A/B-phase pulse from the synchronous encoder to the

next axis, enabling a system the second and later axes are synchronized with the synchronous encoder.

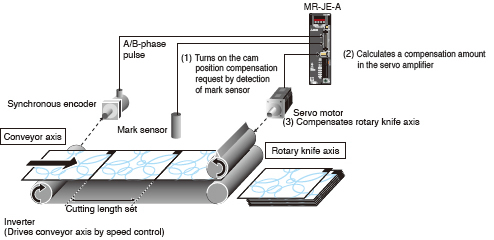

Compensating a position gap by sensor input

Mark Sensor Input Compensation Function

The actual position of the servo motor can be obtained based on the inputs from the sensor that detects the registration marks

printed on the high-speed moving film. The servo amplifier calculates compensation amounts and corrects position errors of the

rotary knife axis based on those inputs from the sensor so that the film can be cut at the set position.

Positioning Using Communication Function

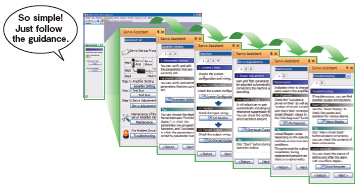

Compatible with MODBUS® protocol

Communication Function (MODBUS® RTU)

In addition to RS-422 communication (Mitsubishi general-purpose AC servo protocol), RS-485

communication (MODBUS® RTU protocol) is supported.

MODBUS® RTU protocol is compatible with function code 03h (Read holding registers), etc.

Controlling and monitoring the servo amplifier by external devices is possible.

Compatible function code

While the point table is in operation, the next target position of

the point table can be overwritten.

While the point table is in operation, the position data is latched

by the mark detection function, and the current position latch

function let the controller to obtain the latched data.

Easy Monitoring and Maintenance

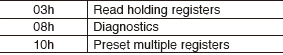

Analyze cause of alarm

Large Capacity Drive Recorder

● Servo data such as motor current and position command before and after the alarm occurrence are stored in non-volatile

memory of the servo amplifier. Reading the servo data on MELSOFT MR Configurator2 helps you analyze the cause of the alarm.

● Check the waveform ((analog 16 bits x 7 channels + digital 8 channels) x 256 points) and the monitor values of 16 alarms in the

alarm history.

Reduce machine downtime incurred by age-related deterioration

Vibration Tough Drive

Machine resonance suppression filter is automatically

readjusted when a change in machine resonance

frequency is detected by the servo amplifier. Losses

from the machine stop due to age-related deterioration

are reduced.

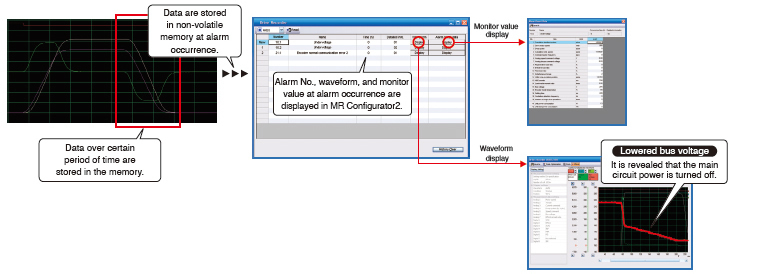

Support optimal maintenance of driving parts

Machine Diagnosis Function

This function detects changes of machine parts (ball screw, guide, bearing, belt, etc.) by analyzing machine friction, load moment of

inertia, unbalanced torque, and changes in vibration component from the data inside the servo amplifier, supporting timely maintenance

of the driving parts.

Easy troubleshooting

Three-Digit Alarm

MR-JE series displays the alarm No. in three digits

to show the servo alarm in more details,

making troubleshooting easy.

User-Friendly Motors

Even in severe environment

Improved Environment Safety

HG-KN series and HG-SN series are rated IP65 and IP67

respectively.

* The shaft-through portion is excluded.

Cable leading in both ways

Selectable Cable Leading Direction

The power cable, the encoder cable, and the electromagnetic

brake cable are led out to either in direction of or in opposite

direction of the load side, depending on the selected

cables. (HG-KN series)

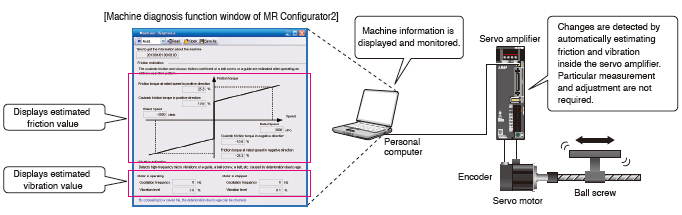

Setup Software

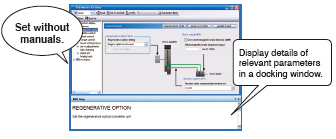

Preparation

Just follow the guidance, and setup is complete

Servo Assistant Function

Complete setting up the servo amplifier just by following

guidance displays. Setting parameters and tuning are easy

since related functions are called up from shortcut buttons.

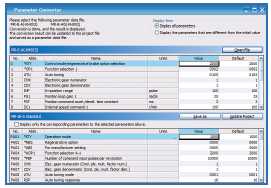

Supporting replacement from conventional system

Parameter Converter Function

With this function, parameter files for MR-E series or MR-E

Super series are converted to those for MR-JE-A series.

Setting and Start-up

Easy and fast parameter setting

Parameter Setting Function

Display parameter setting in list or visual formats, and

set parameters by selecting from the drop down list. Set

in-position range in mechanical system unit (e.g. µm).

Parameter read/write time is approximately one tenth of the

conventional time.

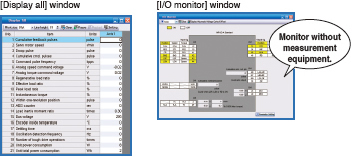

Visible operation and power status

Monitor Function

Monitor operation status on the [Display all] window. Check

power consumption without any measurement equipment

such as electric power meter, assign input/output signals,

and monitor ON/OFF status on the [I/O monitor] window.

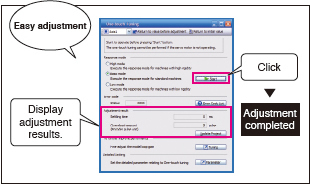

Servo Adjustment

Tuning is just one click away

One-Touch Tuning Function

Adjustments including estimating load to motor inertia ratio,

adjusting gain, and suppressing machine resonance are

automatically performed for the maximum servo performance

just by clicking the start button. Check the adjustment results

of settling time and overshoot.

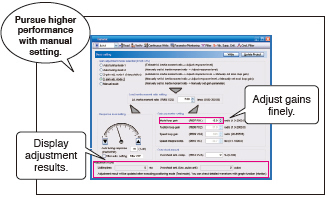

Fine tuning of loop gain

Tuning Function

Adjust control gain finely on the [Tuning] window manually

for further performance after the one-touch tuning.

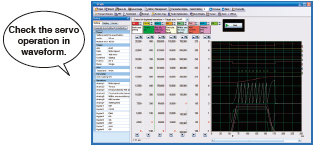

Convenient with overwrite and graph history functions

Graph Function

The number of measurement channels is increased to 7 channels

for analog, and 8 channels for digital. Display various servo

statuses in the waveform at one measurement, supporting setting

and adjustment. Convenient functions such as [Overwrite] for

overwriting multiple data and [Graph history] for displaying graph

history are available.

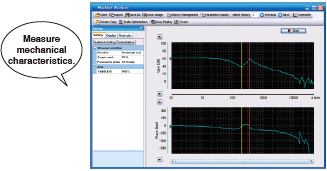

Analyze the frequency characteristics

Machine Analyzer Function

Input random torque to the servo motor automatically and

analyze frequency characteristics (0.1 Hz to 4.5 kHz) of a

machine system just by clicking the [Start] button. This

function supports setting of machine resonance suppression

filter, etc.

Maintenance

For timely parts replacement

Servo Amplifier Life Diagnosis Function

Check cumulative operation time and on/off times of inrush relay. This

function provides an indication of replacement time for servo amplifier

parts such as capacitor and relays.

Find out the aging deterioration of machines

Machine Diagnosis Function

This function estimates and displays machine friction and

vibration in normal operation without any special measurement.

Comparing the data of the first operation and after years of operation helps to find out the aging deterioration of a

machine and is beneficial for preventive maintenance.