View Product Details

With consumer needs rapidly evolving towards increased diversification and reduced time to market, today’s manufacturers face a time of considerable change. It is no longer enough for industrial robots to simply perform a single task. The RV-FR Series vertical six-axis robot provides new, intelligent solutions, offering a simple approach to advanced and flexible production.

KEY BENEFITS

- Robot Diamond Assurance™ – Protect your robot investment with Robot Diamond Assurance, our extended preventive maintenance program. With regular, proper maintenance from Mitsubishi Electric factory trained technicians, obtain increased uptime and fewer repair costs.

- Internal pneumatic and electrical connections – Easily connect to a large range of peripheral devices, from 3D vision systems to padding modules.

- Next generation intelligent functions – Carry out more complex tasks with intelligent technology, such as enhanced vision and force sensors.

- Safe, collaborative work applications – Allow robots and people to work together in a secure environment with safety add-ons such as area scanners and the MELFA Safe

Plus module.

- Open architecture MELFA Basic IV platform – Use a powerful, accessible robot operative system that does not require costly software adders.

- Additional axis interface – Eliminate the need for additional motion controllers by directly controlling up to two external 3-axis coordinated servo systems, with up to 8 total servo axes.

- Remote access capable – Conveniently monitor and control robot operation remotely.

- Convenient ports, features, and add-ons – USB 2.0 port for quick PC connection, SD memory card slot for data logging, and battery free controller provides a worry-free solution to program storage to eliminate waste.

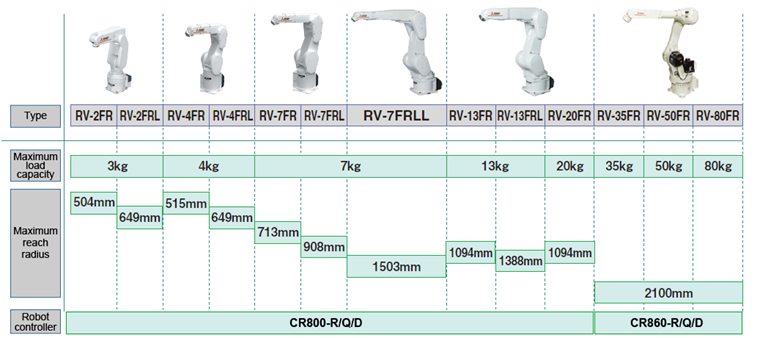

BROAD SIZE LINEUP

RV-FR robots are available in load capacities from 2kg to 20kg, with reach radii ranging from 504mm to 1,094mm.

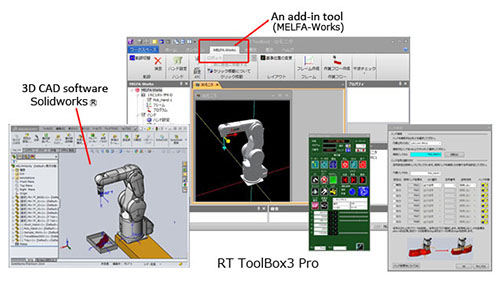

RT TOOLBOX3 PRO: ADVANCED 3D

ROBOT SIMULATOR

RT ToolBox3 PRO is a 3D robot simulator that provides powerful support for system designs and preliminary layout examinations. It allows robot simulations to be run in SolidWorks® 3D CAD software. Programs can be created to match today’s era of high-mix, low-volume production, such as for layout considerations prior to introducing robots, desktop program debugging, and generation of complex motion paths.

View Product Details