Service

Legacy Product Support

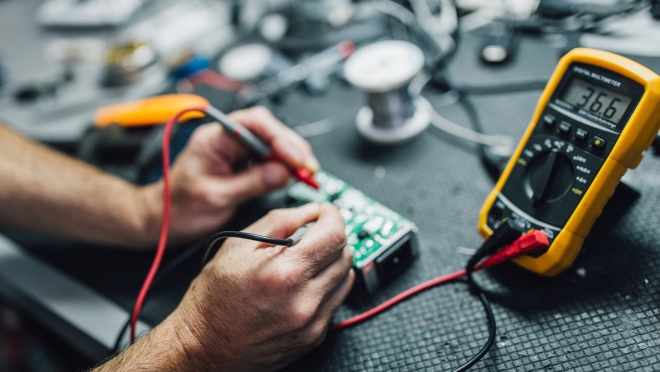

Protecting your investment in Mitsubishi Electric products is one of our top priorities. It is why we continue to support our products since 1974. You can trust our service experts to help you get the most from your investment, no matter the age, and to keep your operations running smoothly and efficiently.

Over time, your product may not perform as well as it did on day one. Maybe your control takes a long time to power on in the morning or locks up in the afternoon, perhaps your spindle speed is becoming erratic or you are experiencing mis-position on one of your axes. We are here to help bring your CNC, servo drive, or spindle drive as close to day one performance as possible. Below you will find some of the checks and replacements we will perform on your legacy equipment. We will also inform you if the equipment should be sent in for cleaning and inspection and make recommendations if any components are operating below standards. We will also inform you of any retrofit options for your products.

Product series we perform service on:

Note: If you do not see your product listed, contact us to discuss available options.

FX, GX, LX Controls - Verify NC communications, create NC backup, check and replace batteries (if needed), verify power supply voltages, check for contamination, inspect and replace fans(if needed), and check screen.

TRA Servo Drives - Check and adjust droop and gain, check motor resistance levels, check base components (transistors, diode stack, contactor) and PU power unit, check motor brushes, clean commutator, inspect and replace fans (if needed).

TRS Servo Drives – Check and adjust droop and gain, check motor resistance levels, check base components (transistors, diode stack, contactor) and PU power unit, inspect and replace fans (if needed).

DL Spindle Drives – Check brushes (motor, tach generator), clean commutator (motor, tach generator), check motor resistance levels, check and adjust field current, check base components (SCRs, diodes, contactor), verify drive voltages, verify spindle operation (speed, orient, direction), inspect and replace fans (if needed).

FR Spindle Drives – Check and adjust DC-CT offsets, check motor resistance levels, check base components (transistors, diode stack), verify drive voltages, verify spindle operation (speed, orient, direction), check parameters and dip switches, inspect and replace fans (if needed).

Learn How We Can Support Your Legacy Products

-

Inquiries

-

Select

& Quote -

Share

-

Partners