-

Inquiries

-

Select

& Quote -

Share

-

Partners

MELSERVO-J5 Series Servo Amplifier

Maintainability

- Feature

- Specification

- Standards

- Discontinued

Predictive Maintenance

Maisart is an abbreviation for "Mitsubishi Electric's AI creates the State-of-the-ART in technology." Mitsubishi Electric is leveraging original AI technology to make devices smarter.

Machine Diagnosis (Ball Screws/Linear Guides)

This function supports predictive maintenance by estimating frictions and vibrations of mechanical drive components such as ball screws and linear guides.

- Friction failure prediction with the friction estimation function

- Vibration failure prediction with the vibration estimation function

Machine Diagnosis (Belts)

This function detects aging deterioration of belts in advance by the static friction failure prediction and the tension deterioration prediction with the belt tension estimation.

- Static friction failure prediction

- Belt tension deterioration prediction

Machine Diagnosis (Gears) *1

With this function, the servo amplifier generates commands automatically, and executes to-and-fro positioning operation to estimate the amount of gear backlash. Gear failure is predicted based on the set nominal values for backlash.

- Backlash estimation function

- Gear failure prediction

- *1.The machine diagnosis (gears) does not work during normal operation.

Preventive Maintenance

Machine Diagnosis (Mechanical Drive Components)

This function estimates when a machine failure will occur based on the total travel distance of the servo motor and notifies when it is time for replacement if the rated service life of the mechanical drive components is set.

- Machine total travel distance failure prediction

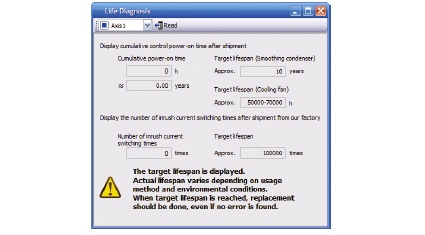

Servo Amplifier Life Diagnosis

This function displays the cumulative energization time and the number of inrush relay on/off times. The data can be used to check the service life of the parts as a rough guide.

- Cumulative energization time (Smoothing condenser/

cooling fan life span) - The number of inrush relay on/off times (Inrush relay life)

Corrective Maintenance

Drive Recorder

This function continuously monitors the servo status and records the status transition such as a trigger condition before and after an alarm for a fixed period of time. Reading the servo data on MR Configurator2 helps you analyze the cause of the alarm. In addition to the monitor values and the waveform of the past 16-time alarms in the alarm history, the system configuration and the servo parameters are displayed. Alarm occurrence time is also displayed when the servo amplifier and the controller are normally in communication on CC-Link IE TSN.

The data can be outputted to a GX LogViewer format file.

Connection/Communication Diagnosis

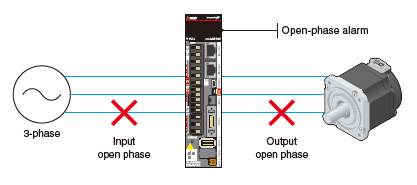

Disconnection Detection

The servo amplifiers are equipped with both input open-phase detection and output open-phase detection. Input open-phase detection detects an open phase of the main circuit power supply of the servo amplifier, and output open-phase detection detects an open phase of the servo motor power supply. The alarm can be distinguished from other alarms such as the overload alarm, reducing the time required to restore the system.

MR-J5D-G4 drive units support only output open-phase detection.

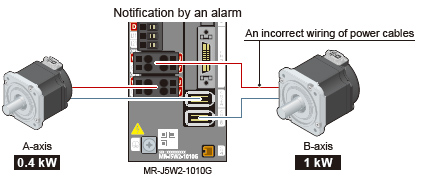

Servo Motor Incorrect Wiring Detection

Multi-axis servo amplifiers MR-J5W2-G/MRJ5W3-G detect servo motors with a different capacity that are incorrectly connected to the A-axis/B-axis/C-axis, contributing to servo motor protection. The servo amplifiers obtain the capacity information of the connected servo motors from the encoders and check whether the servo motors which are connected to the power connectors match the capacity information. If the information is not matched, an alarm occurs.*1

- *1.The incorrect wiring detection does not work for servo motors with the same capacity.

Encoder Communication Diagnosis

The encoder communication diagnosis checks the encoder communication circuit in the servo amplifier. This function is useful for classifying the cause of errors (such as disconnected encoder cables) when the encoder communication alarm occurs.