Blogs

Calculating ROI: Is Robotic Machine Tending Worth the Investment?

Make data-driven decisions. Invest more confidently. Understand your machining potential. This article breaks down an ROI equation for robotic machine tending in clear, practical terms, helping machine shop owners understand how automation can reduce labor costs, boost productivity, and future-proof operations.

The machine tool industry has long been the backbone of modern manufacturing. The industry dates back to the early 19th century, when manually operated lathes and milling machines revolutionized production. Over time, innovations such as CNC (Computer Numerical Control) transformed these tools into programmable powerhouses, enabling greater precision and repeatability. The industry is now undergoing another major shift driven by automation and robotics. Robotic machine tending is no longer an intangible, futuristic concept. It is now a practical solution for manufacturers seeking to optimize efficiency, reduce labor costs, and stay competitive. But with this evolution comes a critical question: Is the investment in robotic machine tending systems truly worth it?

In this blog, we’ll explore how to calculate ROI and determine whether automation is right for your operation.

What is Robotic Machine Tending?

First, we must understand what robotic machine tending entails and where it can provide the most value. Robotic machine tending refers to the automated process of loading and unloading parts into machine tools such as CNC mills, lathes, grinders, injection molding machines, and stamping presses using industrial or collaborative robots. These systems are typically equipped with end-of-arm tooling (EOAT) such as grippers or vacuum systems and often integrate with vision systems and sensors to ensure precise part handling and orientation. Robotic tending can be applied across various industries. For example, high-volume, high-precision machining is critical in automotive, aerospace, and medical device manufacturing. With less human intervention, there is less human error. Robotic machine tending also unlocks the potential for lights-out manufacturing.

Advantages of Robotic Machine Tending

The advantages are substantial: robots can operate continuously across multiple shifts without fatigue, significantly increasing spindle uptime and throughput. They also reduce reliance on manual labor, which is especially valuable amid skilled labor shortages. By minimizing human intervention, robotic tending enhances workplace safety, reduces scrap rates due to consistent handling, and enables manufacturers to reallocate human workers to higher-value tasks such as quality control or process optimization. The result is a leaner, more agile production environment with faster cycle times and improved overall equipment effectiveness (OEE).

Achieving ROI with Robotic Machine Tending

For machine shop owners, every investment is a calculated risk with high stakes. The financial burden of running a shop can be overwhelming. Rising labor costs, unpredictable turnover, and the constant pressure to meet tighter deadlines are challenges felt by nearly every machine shop. In addition, equipment upgrades, maintenance, training, and compliance with safety standards all add up.

The upfront costs of robotic machine tending, such as hardware, integration, programming, and support, can feel daunting when considering automation. But many choose to make this investment to stay competitive. Not only are shops achieving a solid return on investment, but they can also maintain quality and future-proof their operations in an industry that’s evolving faster than ever. That’s why having the support of a trusted automation partner is so critical. A knowledgeable vendor can help guide the decision-making process, tailor solutions to specific needs, and provide ongoing support that ensures the system delivers long-term value, not just a one-time fix.

The ROI Equation

At its core, ROI is calculated as:

ROI (%) = ((Net Gain from Investment−Cost of Investment) / Cost of Investment) × 100

To apply this to robotic machine tending, consider the following:

- 1. Initial Investment

- Robot hardware and end-of-arm tooling

- Integration and programming

- Safety equipment (e.g., fencing, sensors)

- Training and installation

- 2. Ongoing Costs

- Maintenance and support

- Occasional reprogramming or upgrades

- 3. Tangible Gains

- Labor cost savings (e.g., replacing or reallocating operators)

- Increased machine uptime (robots don’t take breaks)

- Higher throughput and consistency

- Reduced scrap and rework

- 4. Intangible Benefits

- Improved worker safety

- Enhanced product quality

- Greater flexibility in scheduling

Applying this Equation with an Example:

Let's say:

- IA robot system costs $150,000.

- It replaces one operator earning $50,000/year.

- It increases machine utilization by 20%, adding $30,000/year in value.

- Annual maintenance is $5,000.

Yearly Net Gain = $50,000 (labor) + $30,000 (utilization) - $5,000 (maintenance) = $75,000

ROI in Year 1 = ((75,000−150,000)/150,000)×100 = −50%

However, by Year 2, the system will have paid itself off, and ROI will have become positive and will continue compounding.

Is the Investment Worth it for You?

Deciding whether robotic machine tending is worth it is a deeply personal decision that depends on your shop's unique challenges and goals. Maybe you're struggling to find reliable operators, or your team is stretched thin trying to keep up with growing demand. You might wonder if automation could help you scale without sacrificing quality or burning out your workforce. These are real concerns, and they deserve careful consideration. The key is to look beyond the upfront cost and ask:

What would it mean for my business if I could run more parts per shift, reduce downtime, and free up my skilled workers for higher-value tasks?

If the answer points toward long-term stability, growth, and peace of mind, then robotic machine tending might not just be worth it. It might be exactly what your shop needs to thrive.

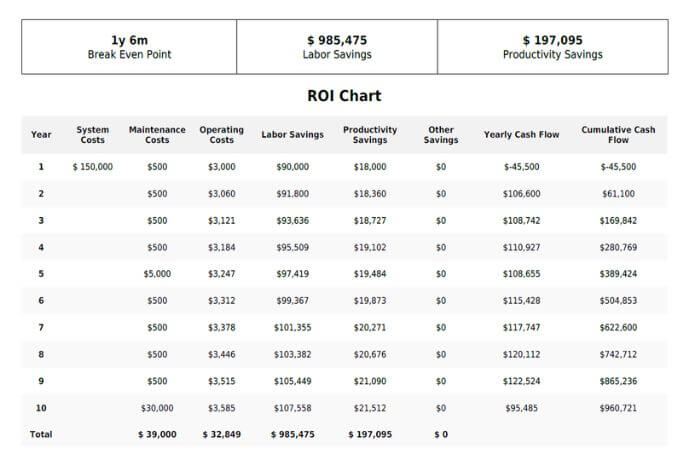

At Mitsubishi Electric Automation, transparency is important to us. We encourage you to try our ROI Estimator Tool so that you can make a confident decision. After you input your unique calculations, the tool will output results so that you can evaluate them with your team before taking that next step. When you’re ready, we’re here to discuss your options.

Conclusion

When making a significant investment like robotic machine tending, having the right partner by your side can make all the difference. Mitsubishi Electric Automation brings over 50 years of machine tool experience and has produced robots for over 40 years. We offer not just cutting-edge technology, but a deep understanding of shop owners' daily challenges. Our solutions are built for reliability, precision, and long-term value, but our commitment to support truly sets us apart. With 24/7 technical assistance and a team invested in your success, you never have to navigate automation alone. Choosing Mitsubishi Electric Automation means gaining a partner who’s there for you from planning to production, and every shift in between.

Want notifications for new Blogs, White Papers, Case Studies & Webinars?

Contributors

Patrick Varley

Product Marketing Manager (Robot)

Mitsubishi Electric Automation, Inc.

-

Inquiries

-

Select

& Quote -

Share

-

Partners