Blogs

Using VFDs to Convert Single-Phase Power to Three-Phase Power in Remote Locations

Are you looking for a solution to run three-phase equipment in remote or off-grid locations with only single-phase power? Discover how Variable Frequency Drives (VFDs) offer a modern, efficient, and cost-effective solution, complete with advanced motor control, energy savings, and remote diagnostics. Whether you're on a farm, job site, or small workshop, this blog describes how VFDs can reliably power your operations.

In remote and off-grid locations, ensuring a reliable and efficient three-phase power supply can be challenging, especially when only single-phase electricity is available. These areas may include rural farms, residential homes, construction sites, suburban developments, and small industrial workshops. Traditionally, rotary phase converters have been used to convert single-phase to three-phase power. While effective for powering multiple machines, they have drawbacks such as audible noise, high maintenance, and energy inefficiency.

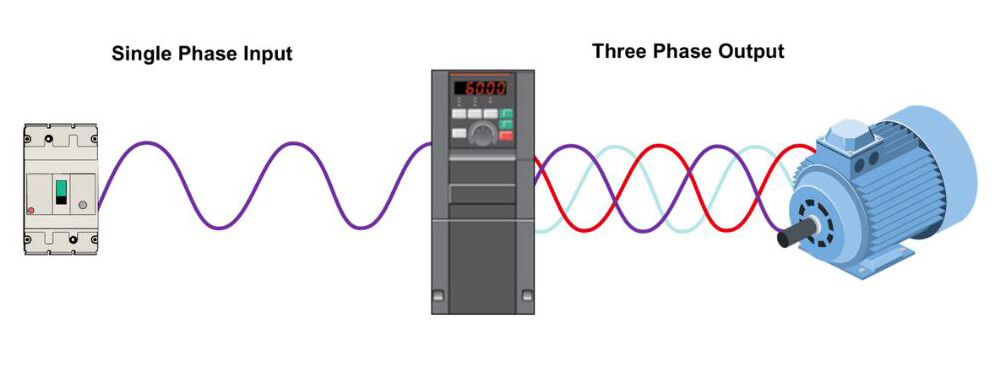

A more modern and efficient solution is a Variable Frequency Drive (VFD). VFDs are electronic devices that not only convert single-phase input to three-phase output, but also offer precise motor control including speed, torque, and position. This article explores the advantages of using VFDs in remote locations, including installation tips, cost savings, sustainability benefits, and technical specifications.

How VFDs Convert Single-Phase to Three-Phase Power

So, how exactly does a VFD take single-phase power and turn it into three-phase power? Let's break it down into a few simple steps:

- First, it converts AC to DC.

The VFD starts by taking the single-phase AC power and running it through a rectifier, usually a diode bridge or an active front end. This process turns the alternating current (AC) into direct current (DC). - Then it smooths things out.

Once the power is in DC form, it goes through a filter made up of capacitors (and sometimes inductors). This step helps reduce voltage ripple and prepares the power for the next stage. - Next, it creates synthetic three-phase power.

Using IGBTs (Insulated Gate Bipolar Transistors), the VFD chops up the DC voltage and reassembles it into a synthesized three-phase AC output. This is done using a technique called Pulse Width Modulation (PWM), which controls the voltage and frequency very precisely. - Optional: Clean up the output.

If you're powering sensitive equipment, you might add an output filter to protect the motor by preventing motor bearing currents and reducing audible noise. Filters can also be used to increase the distance from the motor to the VFD.

The result? A clean, controllable three-phase power supply from a single-phase sourcethat is ideal for running motors and equipment in places where three-phase service isn't available.

VFD Installation Challenges and Solutions in Remote Environments

One of the most common challenges faced when installing VFDs in remote locations is harmonic distortion. Since single-phase VFDs can introduce harmonics into the power system, it's essential to plan for mitigation. This is where line reactors or harmonic filters come into play, especially if you aim to meet standards such as IEEE 519. Another concern is inrush current during startup, which can cause voltage sags and affect other equipment on the same line. Fortunately, many VFDs come with soft-start features or pre-charge circuits. They help to smooth out the power draw and reduce the impact on the system.

Electromagnetic interference (EMI) and radio-frequency interference (RFI) are also worth considering. This may occur from an improperly installed VFD. If not properly managed, these can disrupt nearby sensitive electronics. Using shielded cables and ensuring proper grounding practices can go a long way in keeping interference in check.

On the thermal side, even though VFDs are quite efficient, typically operating at 95 to 98 percent, there's still some heat to deal with. That leftover energy needs to be dissipated, so it's essential to calculate the heat load and size your enclosures accordingly. Most VFDs are rated for ambient temperatures up to 40°C, but if you're working in hotter environments, you may need to derate the drive or add forced cooling to keep things running smoothly.

Applications Where VFDs Can Support Three-Phase Equipment

VFDs aren't just theoretical solutions; they're making a real difference in the field. Take agriculture, for example. Farmers in remote areas use VFDs to power irrigation pumps, grain dryers, and ventilation systems, all from single-phase lines. In construction, VFDs run mixers, compressors, and saws on job sites where three-phase power isn't available. Even small manufacturing shops in off-grid locations rely on VFDs to operate CNC machines and conveyors. Some users report a 30% reduction in energy costs and a significant drop in equipment downtime after switching from a rotary phase converter to a VFD system.

Utilizing a VFD to Its Full Potential

Performance Monitoring and Remote Diagnostics

While providing support for three-phase equipment, VFDs can provide additional, sometimes hidden benefits. For instance, many models now have built-in diagnostics and remote monitoring capabilities. Through IoT integration or SCADA systems, engineers can track performance metrics such as voltage, current, temperature, and fault history in real time. This allows for predictive maintenance to catch issues before they become problems and help optimize system performance. Some VFDs even support alerts via email or SMS, so you're always in the loop, even when off-site.

Regulatory Compliance and Safety Standards

When installing VFDs, it's essential to stay compliant with industry standards and safety regulations. For example, IEEE 519 provides guidelines for harmonic distortion, which is especially relevant when using single-phase VFDs. Look for VFDs that carry UL or CE certifications to ensure they meet electrical safety requirements. And don't forget about local codes, compliance with the National Electrical Code (NEC) is essential for safe and legal installations. Following these standards not only protects your equipment but also ensures the safety of personnel and the reliability of your power system.

Conclusion

Whether you're powering a remote farm, a construction site, or a small industrial workshop, VFDs offer an innovative, efficient, and reliable way to convert single-phase power into three-phase output. There are countless benefits: energy and cost savings, reduced maintenance, advanced motor control, and remote diagnostics.

If you're looking for a reliable solution and industry-leading support, contact Mitsubishi Electric Automation. We're known for our robust, high-performance VFDs and experts who can help you design and implement a system that meets your exact needs, no matter how remote your operation may be.

Want notifications for new Blogs, White Papers, Case Studies & Webinars?

Contributors

Benjamin Strong

Industry Marketing Manager (Drive Systems)

Mitsubishi Electric Automation, Inc.

-

Inquiries

-

Select

& Quote -

Share

-

Partners