Blogs

How VFDs Revolutionize Pump Speed Control, Energy Efficiency, and Reliability in Liquid Cooling Systems for Data Centers

Summary: This blog explores how Variable Frequency Drives (VFDs) are transforming liquid cooling systems in data centers and other industries. It covers the benefits of VFDs, including energy efficiency, predictive maintenance, and harmonic mitigation, and highlights their role in adaptive, future-ready cooling solutions.

Variable Frequency Drives (VFDs) are revolutionizing liquid cooling systems. Their adaptive nature enhances energy efficiency, improves reliability, and enables advanced predictive maintenance. Discover how VFD liquid cooling solutions can lead to substantial operational savings, enhanced system control, and future-ready solutions in high-performance environments.

The Critical Role of Liquid Cooling Control in Modern Data Centers

Data centers are a hot topic today. They are both top of mind, while actually being hot. As the chips within data centers process and distribute information, they emit heat, requiring a precise temperature management system.

While HVAC systems have been the most common solution, more advanced innovations, such as liquid cooling, are gaining popularity. Liquid cooling utilizes water to dissipate the heat generated by the chips. Variable frequency drives (VFDs) are a common solution for controlling motors that pump water due to their energy-saving benefits and reliability within systems. After all, today's reliance on data centers leaves no time for downtime.

In this article, we explore how VFDs contribute to an advanced liquid cooling system that is future-proof, discussing its unique features, including energy and operational efficiency, predictive maintenance, and harmonic mitigation.

To discover Mitsubishi Electric Automation's complete solution for liquid cooling control systems, click here.

Understanding VFDs in Liquid Cooling Technology

Many view VFDs as electronic controllers merely meant to control the speed and torque of electric motors. But they're more than just that. These drives facilitate seamless integration with automation systems, enabling real-time adjustments based on sensor feedback. This ensures that the cooling system operates precisely within the required thermal parameters. That way, the system isn't overcooled or overheated.

VFDs are sophisticated devices that can adjust the input frequency and voltage to provide an adequate amount of energy when needed. The heat emitted by chips fluctuates, and VFDs maintain optimal coolant flow in response to demand. That dynamic response capability makes VFDs indispensable in advanced liquid cooling technology, where maintaining optimal coolant flow is crucial for effective heat dissipation and process stability.

How VFDs Match Pump Output to Workload Demands for Dynamic Pump Speed Adjustment

VFDs ensure that the liquid cooling system efficiently meets the changing demands of the workload. They do this by:

- 1. Continuously changing the pump’s rotational speed based on real-time feedback from temperature and pressure sensors

- Ensures the pump output matches workload demands, providing optimal performance and adaptability. Other solutions for driving pumps, such as soft starters, have a limit on the number of excitations per hour. This means less responsiveness to the system’s requirements.

- 2. Lowering the pump speed when the system detects a reduced thermal load

- Reduces energy consumption and operational noise, saving costs and creating a quieter environment.

- 3. Raising the pump’s speed to deliver sufficient coolant flow when needed

- Maintains efficient cooling and protects equipment during high-demand periods.

- 4. Minimizing mechanical stress by adjusting speeds to actual needs

- VFDs can easily adapt to changes in the system, such as variations in inflow rates or changes in the pumping requirements.

- 5. Load characteristic monitoring

- Most modern VFDs have a routine to record load characteristics to detect pump wear from blockages.

Quantifiable Energy-Saving Benefits of VFDs for Liquid Cooling Control

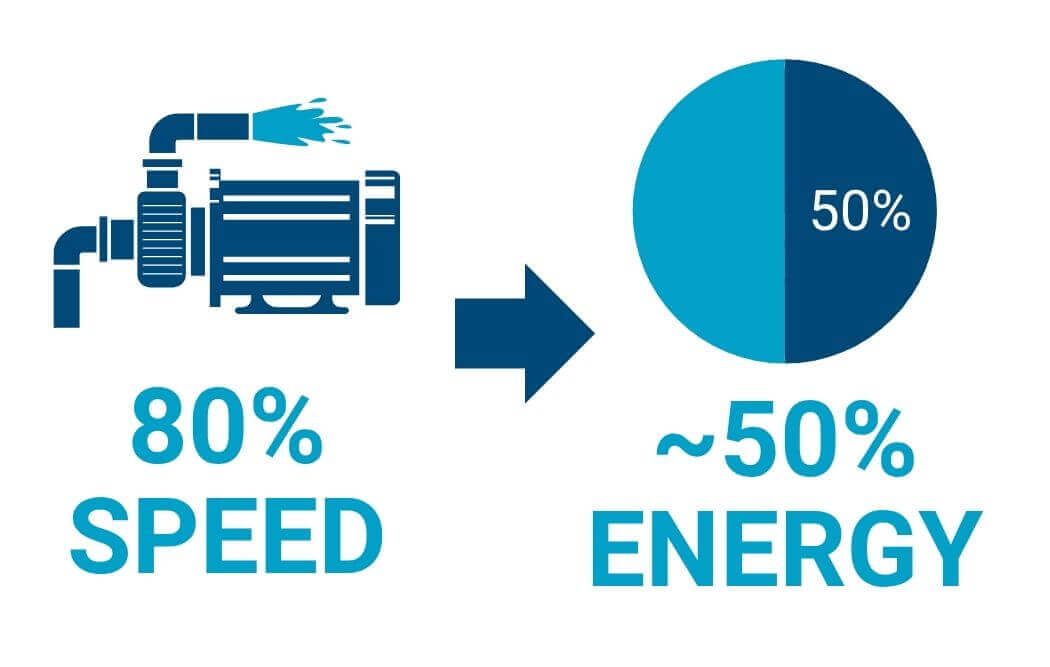

One of the most compelling advantages of integrating VFDs into liquid cooling control technology is their potential for energy savings. According to the affinity laws, when you change the speed of a pump or fan, the amount of power it uses changes much more quickly. If you double the speed, the power used increases by a factor of eight.

Therefore, even modest reductions in pump speed can result in substantial decreases in energy usage. For example, operating a pump with a VFD at 80% of its maximum speed can reduce energy consumption by nearly 50%.

Over time, these savings translate into lower operational costs and a smaller carbon footprint, helping to align with sustainability goals in industrial and data center operations. Moreover, the precise control offered by VFDs eliminates the need for energy-wasting throttling valves or bypass lines.

Predictive Maintenance Enabled by VFDs Leads to Data-Driven Reliability

Modern VFDs can detect anomalies that may lead to or develop faults. They do this by continuously collecting and analyzing data such as:

- Current draw

- Vibration

- Temperature

- Run-time hours

Through real-time data, your maintenance teams can schedule interventions before minor issues escalate into costly failures. This ensures your system stays up and running.

VFDs can also be integrated with supervisory control and data acquisition (SCADA) systems to provide centralized control and monitoring of all liquid cooling control components. A SCADA system can automate alarm triggers for timely preventive actions.

As a result, predictive maintenance in your liquid cooling control solution not only improves system reliability but also optimizes maintenance schedules and resource allocation.

Harmonic Mitigation in Liquid Cooling Systems Enhances Power Quality

The truth about VFDs is that they can introduce harmonics into the electrical power system. Creating a variable frequency causes fluctuations in the system's access to a clean electrical supply voltage. This is measured by the system's Total Harmonic Distortion Percentage (THDP). Harmonics cause potential overheating, equipment malfunctions, and reduced efficiency.

Advanced VFDs feature built-in harmonic mitigation technologies, including

- Multi-pulse rectifiers

- Active filters

- DC ink reactors

These features ensure that harmonic distortion remains within acceptable limits, safeguarding sensitive equipment and maintaining compliance with power quality standards. Effective harmonic mitigation is particularly critical in liquid cooling technology applications, where uninterrupted operation is essential.

While VFDs are top contributors to THDP, the entire system needs to be considered to make sure the facility is compliant. To estimate your current harmonic contribution in your system, try our Harmonics Estimator Tool.

Practical Applications for Liquid Cooling Control and Technology

The integration of VFDs into liquid cooling control systems is transforming various industries, including data centers, semiconductor manufacturing, and power generation.

Liquid Cooling in Data Centers

VFDs help to maintain optimal operating temperatures while reducing energy consumption. The coolant circulation rates are adjusted based on the server's heat output.

Liquid Cooling in Semiconductor Manufacturing

VFDs enable cooling systems to respond instantly to fluctuations in equipment load, ensuring product quality and preventing costly downtime.

Liquid Cooling in Power Generation

VFDs help dissipate heat from turbines and generators, modulating pump speeds to accommodate varying power outputs and ambient conditions.

These specific applications demonstrate the versatility and reliability of VFD-controlled liquid cooling, by enhancing performance, prolonging equipment lifespan, and reducing operational costs.

The Future of Adaptive Cooling and Liquid Cooling Control

Adaptive cooling systems powered by VFDs represent the forefront of liquid cooling technology. By dynamically adjusting pump speed to workload demands, VFDs deliver significant operational savings, enable predictive maintenance, and ensure high power quality through harmonic mitigation. Emerging trends, such as integration with IoT platforms and AI-based control algorithms, promise to further enhance the capabilities of adaptive cooling systems. For technical professionals and engineers, understanding and leveraging the potential of VFDs is essential for designing robust, future-ready liquid cooling solutions.

For a closer look at a complete control solution for liquid cooling, including VFDs, PLCs, HMI, and SCADA, download our eBook.

Want notifications for new Blogs, White Papers, Case Studies & Webinars?

Contributors

Pete Byrnes

Industry Marketing Manager (Data Center)

Mitsubishi Electric Automation, Inc.

-

Inquiries

-

Select

& Quote -

Share

-

Partners