Blogs

4 Undeniable Benefits of Smarter Control:

Why Every Modern Car Wash Needs a Smart VFD

Summary: This blog explains why Smart Variable Frequency Drives (VFDs) are essential in modern car wash systems, highlighting their benefits in energy efficiency, reduced mechanical wear, optimized performance, and reliable network-connected control. It outlines how smart VFDs help operators and OEMs improve uptime, lower maintenance costs, and enhance system flexibility.

Car wash operators and OEMs alike are under constant pressure to reduce costs, maximize uptime, and deliver a superior customer experience. These common challenges create a highly competitive market.

One secret weapon behind successful, efficient, and reliable car washes? The VFD!*

Below, we will illustrate why every modern car wash should make smart VFDs the heart of their pump and blower systems. We will explore the four primary benefits of VFDs for car wash systems:

- 1.Increased energy efficiency

- 2.Reduced wear

- 2.Optimized performance

- 2.Enhanced reliability

- * (Variable Frequency Drives, sometimes referred to as VSD: Variable Speed Drive).

VFD Benefit #1: Energy Efficiency

Energy costs may not be the highest expense for car wash operations compared to labor, chemicals, or building costs, but they are one area that can be quickly improved.

Traditional motor starters (like across-the-line or soft starters) run pumps, blowers, and vacuums at full speed, regardless of actual demand. This "all or nothing" approach can waste electricity, especially during off-peak periods or when partial flow is sufficient.

By precisely controlling the speed and torque of electric motors, VFDs enable pumps and blowers to run only as fast as needed. This is especially beneficial in applications with varying demand. Soft starters do not offer energy savings once the motor reaches full speed, as they only reduce the initial in-rush current.

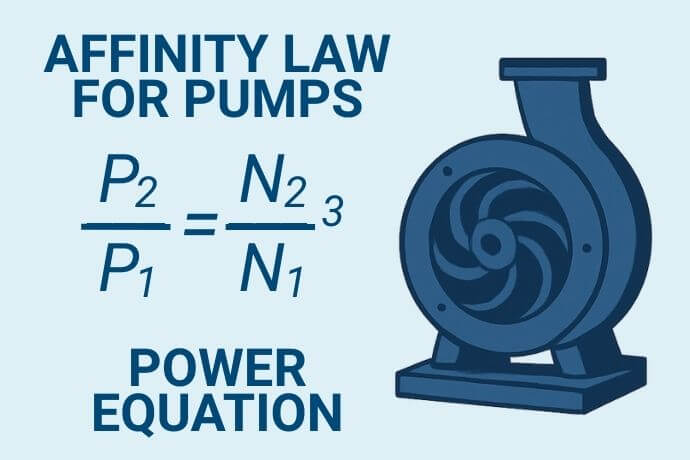

The numbers speak for themselves:

If we think about even a small reduction of 5Hz, we can apply the affinity laws and see potential energy savings of up to 23%. Of course, this depends on your specific pump and pump curve allowance, as well as actual performance at the wash

- Speed Ratio = 55Hz/60Hz = 0.9167

- Affinity Law of Power = (0.9167)³ = .0.770 (77%)

- Energy Reduction = 1-0.770 = 0.230 = 23% savings

VFDs can help car washes meet sustainability goals and comply with new energy-efficiency standards. In car wash systems, they deliver immediate and ongoing energy savings, making your car wash more profitable and sustainable.

Click for Energy Savings Example

VFD Benefit #2: Reduced Mechanical Wear and Tear

Mechanical wear and tear are major contributors to downtime and maintenance expenses for car wash owners. Traditional motor starters subject pumps and blowers to high starting torque. This causes an abrupt acceleration, which may lead to damage and repairs.

VFDs reduce mechanical wear and tear in car wash systems through:

✔ Water Hammer Prevention: Sudden pressure surges (water hammer) can damage critical components such as pipes, valves, and impellers. VFDs address this issue by offering low starting torque and smooth acceleration, minimizing pressure spikes and protecting your system from unnecessary stress.

✔ Extended Equipment Life: High torque and vibration at startup increase radial forces on pump bearings and seals, leading to premature failure. By gradually ramping up motor speed, VFDs significantly reduce these forces, resulting in longer-lasting bearings, seals, and overall equipment.

✔ Torque Monitoring and Limiting: VFDs provide advanced torque monitoring features that help diagnose mechanical issues in pumps and blowers before they become critical. Additionally, torque limiting can be used to prevent damage to customers’ cars from brushes.

For car wash OEMs and operators, investing in VFD technology yields improved equipment longevity, reduced emergency repairs, and lower maintenance costs.

VFD Benefit #3: Optimized Performance

Modern car washes demand more than just "on/off" control. They require precise, flexible, and connected automation to handle variable loads, remote monitoring, and rapid troubleshooting. All of these features help to maximize car wash uptime. This is where smart VFDs truly shine.

Built-in Intelligence features of VFDs

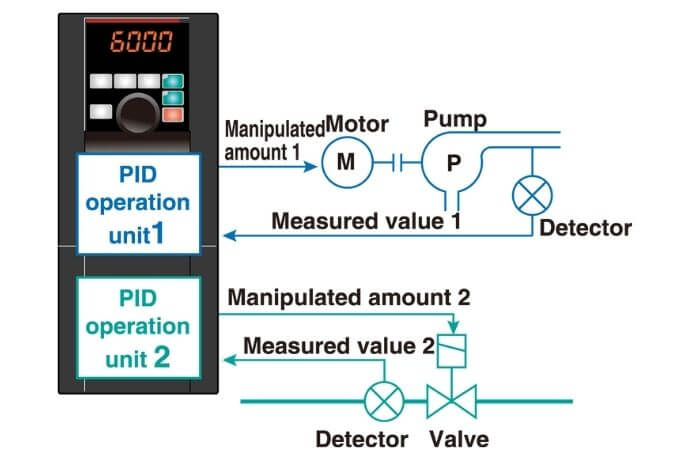

✔ Internal PID Control: VFDs with built-in PID can automatically regulate pump or blower speed to maintain a set pressure or flow, even as demand changes. This is ideal for applications like vacuum systems, intermittent spray pumps, and post-wash blowers.

✔ Internal PLC: Many VFDs now include PLCs (programmable logic controllers), allowing them to handle simple automation tasks (like door lifts or vacuum subsystems) without a separate controller. This reduces panel space, wiring complexity, and cost.

✔ Trace Function: Smart VFDs offer the ability to monitor and store critical troubleshooting information before faults occur. If faults occur, the user can capture the data, which includes frequency, current, temperature, etc., to better understand what caused the alarm. This function is automatic when the trace function is turned on.

VFD Benefit #4: Compatibility with Various Networks

Smart VFDs support modern industrial networks (Ethernet/IP, EtherCAT, Profinet, Modbus TCP, CC-Link, and more).

VFD network compatibility enables:

✔ Plug-and-play connectivity: Daisy-chain multiple VFDs using a single Ethernet cable for rapid installation and expansion.

✔ Centralized monitoring and control: VFDs can report status, alarms, warnings (85% of alarm conditions), and energy usage back to a central PLC, HMI, or SCADA system.

✔ Remote monitoring: Most VFDs now come standard with Ethernet ports built in. Ethernet helps simplify the connection to the cloud. This allows customers to monitor the status remotely from anywhere in the world.

✔ Faster troubleshooting: When a fault occurs, detailed alarm data is instantly available at the HMI or remotely, allowing operators to diagnose and resolve issues quickly.

✔ Greater flexibility: Easily adjust setpoints, schedules, or control logic over the network, so there is no need for manual intervention at each drive.

Overall, network-connected VFDs are ideal for scalable architectures due to their affordability, ease of setup, and support for distributed I/O.

The Smart Control Choice for Modern Car Washes

Every modern car wash needs a VFD. Whether it's for energy savings or for reliability and flexibility, smart motor control helps meet today’s operational demand. By upgrading to VFD-driven systems, car wash owners, operators, and OEMs can focus on what matters: keeping their customers happy with a car wash that doesn’t fail them.

Your trusted VFD provider for over 40 years!

Want to learn more about VFD solutions for your car wash? Contact Mitsubishi Electric Automation for expert advice, case studies, and product recommendations.

The Complete Mitsubishi Electric Control Solution

VFDs are a small part of a total solution. We offer a complete controls package that includes HMIs, PLCs, Remote I/O, SCADA, and more! In a recent article, we explored the smart features of these components and their influence on car wash control systems. Check it out below!

Want notifications for new Blogs, White Papers, Case Studies & Webinars?

Contributors

Tim Hider

Industry Marketing Manager

Mitsubishi Electric Automation, Inc.

-

Inquiries

-

Select

& Quote -

Share

-

Partners