Case Study

Kettering University

First released December 31, 2025

Key Points:

- 1. The Challenge: Bridging the skills gap in modern manufacturing

- 2. The Solution: A smart, programmable, and flexible manufacturing cell

- 3. The Results: Students gain real-world automation experience before entering the workforce

The Challenge - Bridging the skills gap in modern manufacturing

Across the manufacturing sector, a pressing issue looms large: a growing shortage of skilled labor entering the workforce. As industries race to adopt advanced automation technologies, the demand for engineers who can design, operate, and optimize these systems is skyrocketing. That's where educational institutions, like Kettering University, step in.

Kettering University, a STEM-focused institution with a century-long legacy of innovation, recognized this challenge early. Known for its rigorous Co-op model and industry-aligned curriculum, Kettering sought to deepen its students' exposure to real-world automation systems. "Our value add for our students is to make them job-ready, and to have access to state-of-the-art equipment," says Andy Watchhorn, Lecturer, at Kettering University.

The university needed more than just equipment; it required a solution that would evolve with the industry, challenge students creatively, and prepare them for the dynamic world of smart manufacturing.

To bring this vision to life, Kettering turned to two trusted partners: Mitsubishi Electric Automation, a leader in factory automation, and Patti Engineering, a seasoned systems integrator with deep ties to the university. The collaboration was more than business, it was personal for Sam Hoff, Patti Engineering's founder. Sam is a Kettering alumnus and proud parent of a current student. "I love this school. I graduated from here in 1990, and now my son is attending. It's incredibly rewarding to give back in a way that directly impacts students' futures," Sam said.

The Solution: A smart, programmable, and flexible manufacturing cell

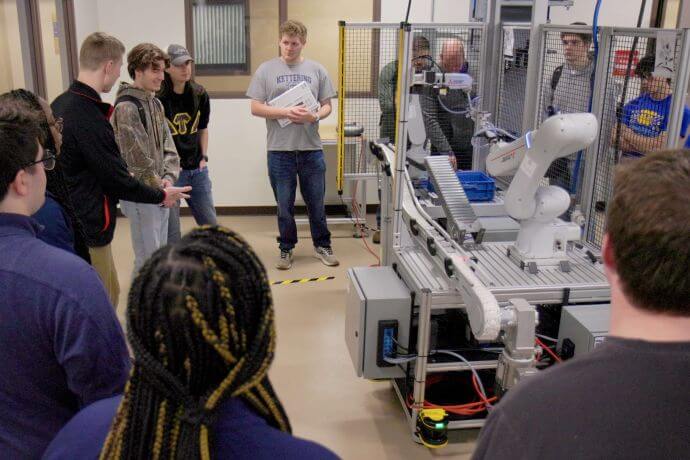

The result of this collaboration is a two-station robotic cell that mirrors the complexity of modern industrial environments. Designed to be modular and upgradable, the system includes an industrial robot and a collaborative robot for dual-mode operation, programmable logic controllers (PLCs) and human-machine interfaces (HMIs), vision systems for object recognition and inspection, and conveyor and gravity feed systems for part movement. "They are advanced components that are similar to those being used in the industry," says Tom Majewski, Business Development Manager (Educational Solutions) at Mitsubishi Electric Automation. He adds, "This type of equipment is cutting edge, challenges students creatively, and gets them excited."

The cell simulates a bin-picking and inspection process: an application commonly found in local manufacturing facilities. Students program the robots to identify, pick, inspect, and sort coins, using real-time data and vision feedback.

While working for today, the system is designed to adapt to new industry trends and needs. "We created a base program that students can build on. Each semester, they can improve the system, add features, and make it better. That's real-world engineering," says systems integrator Sam Hoff.

Scotty Grunwald, Electrical Engineering major at Kettering University '25, claims that the hands-on manufacturing cell is unique compared to his friends at other educational institutions. "This is my first real attempt at an automation system. Before this, my experience was pretty limited." He adds, "None of my friends at other universities have anything like this. They might have a small robot in a lab, but nothing that could go straight into an industrial environment and work fine."

"This equipment allows master’s students to do thesis-level work on a complete system. That’s a game-changer for our curriculum,"

- Andy Watchhorn, Kettering University

The Result: Students gain automation experience before entering the workforce

"Theory and Practice" describes Kettering University's educational model and philosophy. With the new automation cell, students now experience the full lifecycle of a manufacturing system, from design and programming to optimization and data analysis. "It's one thing to solve a differential equation. It's another to move something with dynamics and see it perform a task. That's motivational, and that's what builds expertise," says lecturer Andy Watchhorn. Students are encouraged to iterate, innovate, and push boundaries of what the system can do, while providing support for multiple disciplines from mechanical and electrical engineering to computer engineering.

This collaboration has created new opportunities for Kettering University. "This equipment allows master's students to do thesis-level work on a complete system. That's a game-changer for our curriculum," says Andy. The system serves as an inspiration for not only the students who learn from it, but for the lecturers and the potential for their coursework.

The Diamondworks! Advantage

This initiative is powered by Diamondworks!, Mitsubishi Electric Automation’s workforce development program. Diamondworks! goes beyond equipment development, it provides a full ecosystem of support:

- Curriculum development and instructor training

- Technical support and system commissioning

- Access to Mitsubishi Electric Automation's North American headquarters for training and collaboration

Kettering University Case Study Video

Product and Solutions

Kettering University

- Business: Founded in 1919, Kettering University has pushed the boundaries of technology and engineering. What began as a night school for automotive engineers and technicians has grown into a university that graduates leaders in the automotive industry, aerospace, biotechnology, finance, logistics, consumer products, banking, health care, and many others.

-

Inquiries

-

Select

& Quote -

Share

-

Partners