Case Study

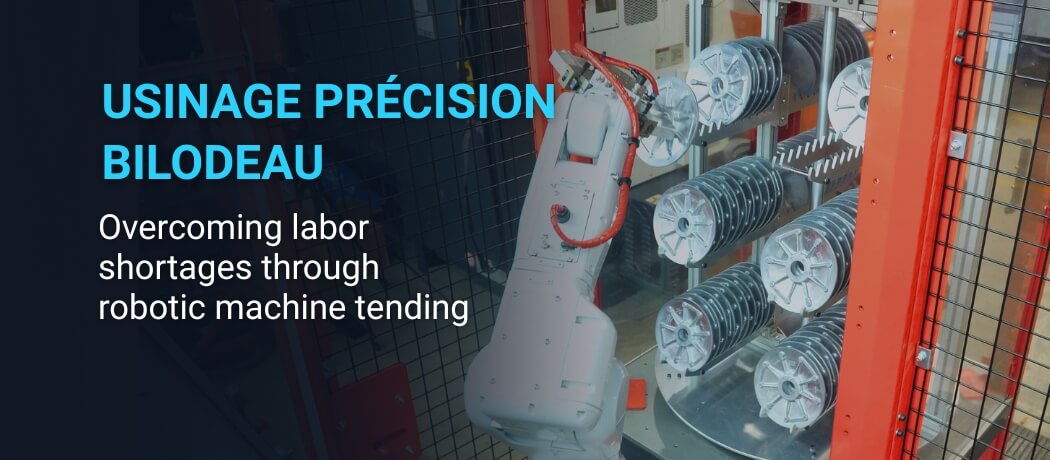

Usinage Précision Bilodeau (UPB)

First released January 15, 2026

Summary: This case study describes an instance where a machine shop, Usinage Précision Bilodeau, was faced with a labor shortage that limited production. By partnering with CTA CNC and Mitsubishi Electric Automation, the company implemented the LoadMate Plus robotic machine tending solution, resulting in resulting in immediate productivity gains and increased operational efficiency.

Key Points:

- 1. The Challenge: Labor shortage limits production capacity for machine shop

- 2. The Solution: Integrated robot and base, LoadMate Plus, to meet the exact needs of the machining operation

- 3. The Result: Immediate productivity gains from automated robotic machine tending

The Challenge - Labor shortage limits production capacity for machine shop

Usinage Précision Bilodeau (UPB), a Quebec-based machine shop, specializes in general machining for both large and small production runs. With eight CNC machines in operation, UPB faced a significant challenge: a shortage of skilled labor and difficulty in hiring for repetitive tasks.

This is a challenge we are seeing among many customers across all industries throughout North America. President of UPB, Yan Bilodeau, shares his company's first-hand experience with the unfruitful labor market. "As it is, we are at, I would say, about 50% of our capacity."

The company needed a solution that would allow them to scale production without relying on hard-to-find labor.

The Solution - Integrated Robot and base, LoadMate Plus, to meet the exact needs of the machining operation

UPB collaborated with CTA CNC, a systems integrator and Diamond Partner of Mitsubishi Electric Automation, based in Quebec. CTA CNC, initially a CNC maintenance and repair company, now provides parts, machine sales, and robotic integration services across the province.

Facing labor shortages, UPB, CTA CNC, and Mitsubishi Electric Automation determined that automation was key to boosting productivity. Emmanuel Deschênes, President at CTA CNC, noted the shift: implementing automation was "able to become very productive, versus an employee with this type of operation."

CTA CNC and Mitsubishi Electric Automation introduced UPB's first robot on a pre-engineered base, LoadMate Plus™, a solution tailored to UPB's CNC machine tending requirements. The system was added to one of their existing CNCs and uses Mitsubishi Electric's RV-8CRL robot, which features:

- 8kg payload

- 931 mm reach radius

- IP65 environmental rating

"With Mitsubishi Electric Automation’s expertise in robotics and CNC, they really helped guide us through this machine tending project."

- Anthony Rancourt

Inside Sales Rep, CTA CNC

Mitsubishi Electric Automation provided both hardware and expert support, leveraging over 50 years of industry experience. As Anthony Rancourt, Inside Sales Representative at CTA CNC, stated, "With their [Mitsubishi Electric Automation's] expertise in robotics and CNC, they really helped guide us through this machine tending project."

The Result - Immediate productivity gains from automated robotic machine tending

The LoadMate Plus solution delivered immediate results for UPB. With a significant increase in productivity and efficiency, UPB can better serve the demands of its customers. Systems integrator CTA CNC found that the integration of Mitsubishi Electric Automation components played a key role in this success. "It is the performance and quality of Mitsubishi Electric Automation that allows our customer to meet those demands," said Anthony.

The success of this first robot implementation quickly led UPB to consider additional automation applications.

Why Work with Mitsubishi Electric Automation for Robotic Machine Tending?

- Quality Products: Reliable, high-performance robotic and CNC solutions.

- Speed to Operation: Fast, effective integration and support.

- Strong Partnerships: Collaborative approach with integrators and end users.

- Full Turnkey Solutions: From planning to implementation, Mitsubishi Electric Automation has proven success in this industry.

Ready to transform your shop's productivity? Mitsubishi Electric Automation delivers the speed, support, and quality you need to succeed.

Contact us today to get started.

Become Our Next Success Story

Product and Solutions

Usinage Précision Bilodeau

- Established: 2019

- Business: A digital machining company, located in Victoriaville, QC CANADA which offers CNC production services for all formats.

CTA CNC

- Established: 2013

- Business: CTA CNC's expertise is in detailed maintenance, repair, and refurbishment of CNC (computer numerical control) machine tools.

-

Inquiries

-

Select

& Quote -

Share

-

Partners