iQ Monozukuri

Andon Solution

iQ Monozukuri Andon provides a solution to easily implement and operate an Andon system. Andon systems are used in manufacturing systems to visualize information from the production floor and share the information with factory workers, production managers, and maintenance personnel.

Andon Solution

Key Benefits:

- Increase operational efficiency – Increase productivity through shared information about production status and changeovers

- Reduce downtime – Visualize the status of various processes to quickly identify and respond to any problems in production

- Easy implementation – Pre-engineered project data minimizes implementation costs, and is easily customizable

- Easy operation – Adjust production schedules without consuming engineering resources to modify the production system

- Remote connectivity – View the production status on a mobile device when the central monitor is not visible

- Multiple client support – Supervisors can access a different screen without affecting the screen shown on the central Andon monitor

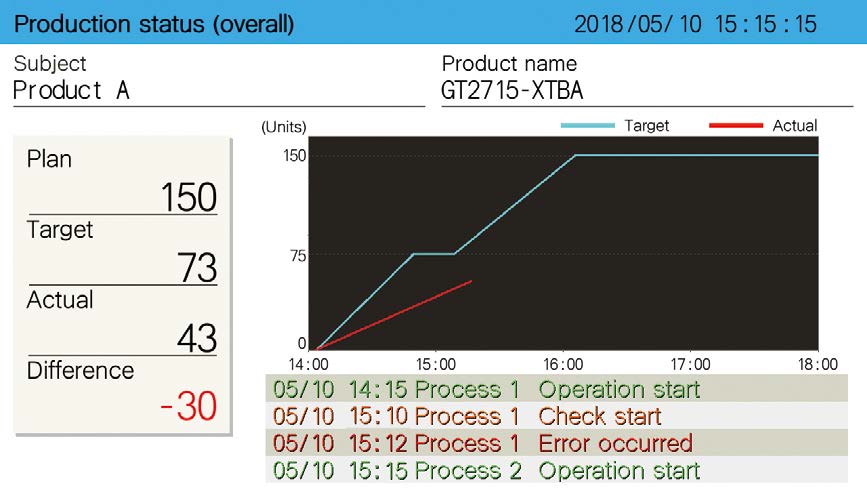

MONITOR PRODUCTION STATUS

Pre-programmed screens display the target quantity and production results graphically in a progress chart, making it easy to check progress and monitor for production delays.

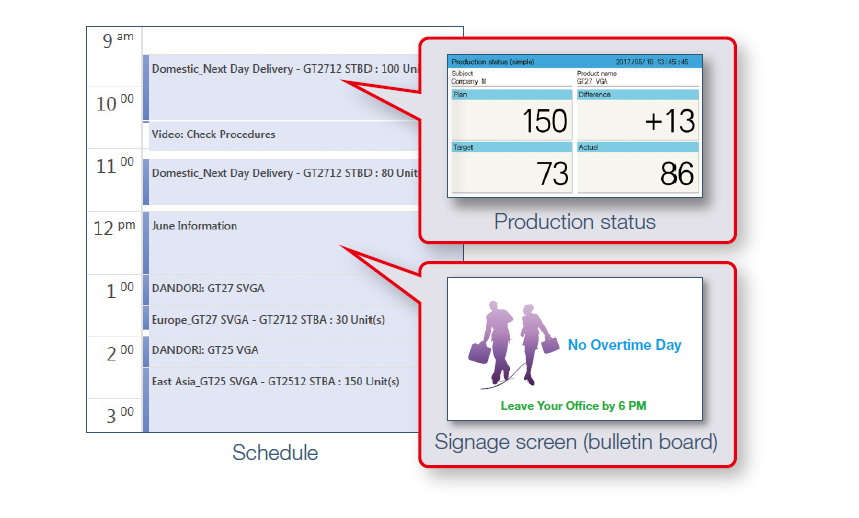

EASILY SET PRODUCTION SCHEDULES

With the included intuitive software, the production plan, uptime status, messages, and even signage screens can be easily set up for display on the Andon monitor.

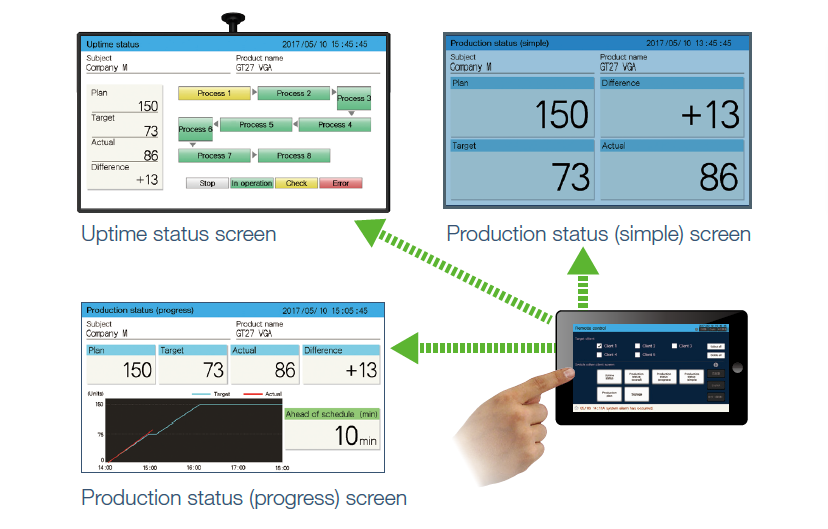

ON-DEMAND SCREEN SWITCHING

Easily change the display screen on the Andon monitor by remote control to see the type of information needed.

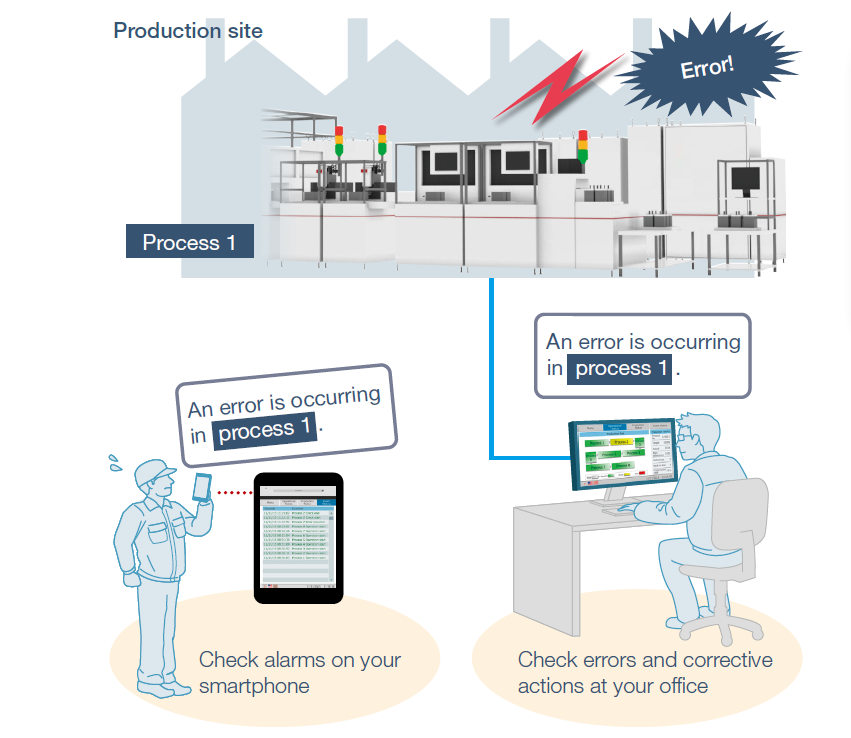

ACCESS ON MOBILE DEVICES

Monitor line status using mobile devices from remote locations anytime, anywhere.

Ready to Connect With Mitsubishi Electric Automation?

How Can We Help You?

-

Inquiries

-

Select

& Quote -

Share

-

Partners