ARIA

General Applications

ARIA for General Applications

ARIA is an ideal solution for common challenges found in the Industrial sector. Assembly/sub-assembly, press tending automation, pick & place, parts transfer, screw driving and dispenser/sealing are just a few of the applications where ARIA is a viable solution to labor, productivity and quality challenges. Our team has done the engineering necessary so you can start running and making parts quickly after delivery for quick ROI and maximum productivity.

FLEXIBLE CONNECTIVITY

Plug & play communication options

Simple connection via Ethernet – Integrating ARIA

into your operation is as simple as plugging in an Ethernet cable. ARIA

offers discreet I/O connectivity over CC-Link IE Field Basic, Ethernet IP,

Profibus or ANYWIRE ASLINK for ease of set-up and performance. End-users

realize fast return on their investment by having the unit up and running

quickly.

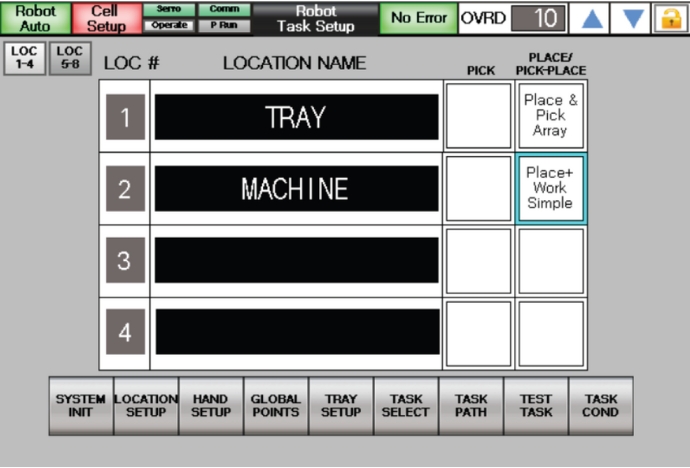

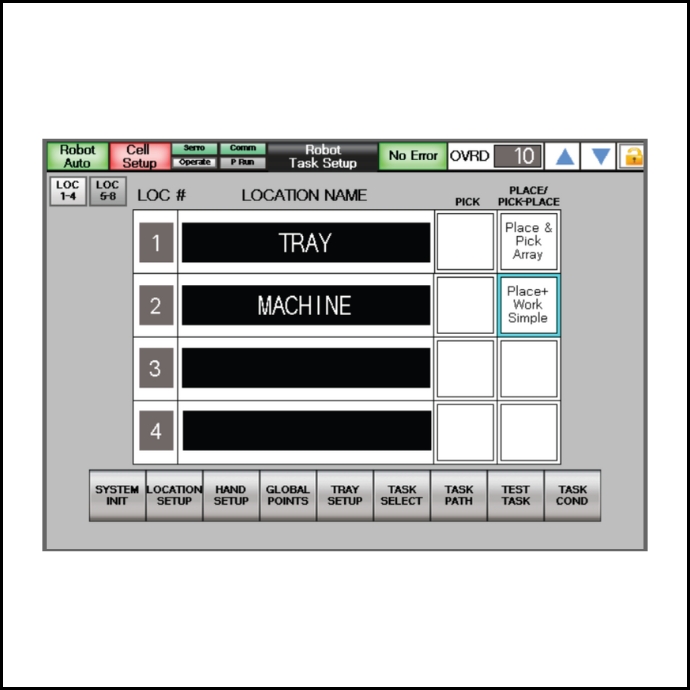

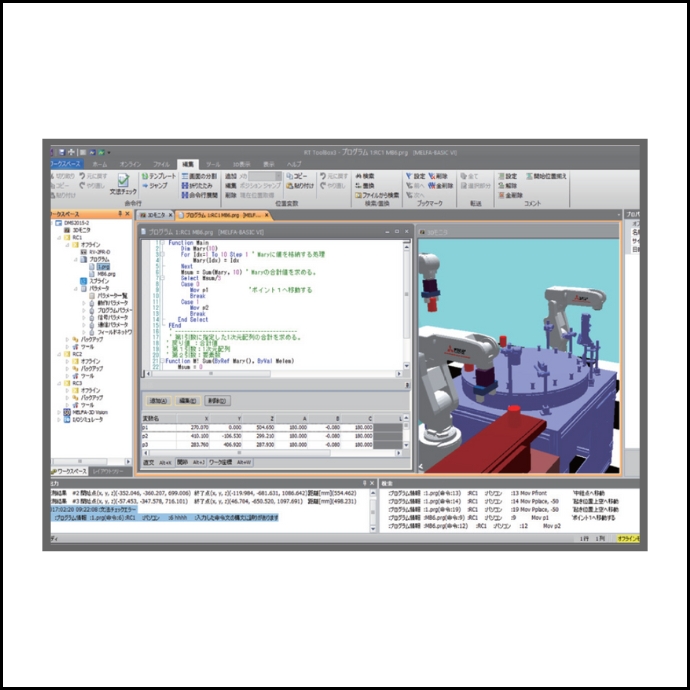

EASY PROGRAMMING

Robot programming for all levels of expertise

Flexible in Design – ARIA can be programmed in a

multitude of ways to satisfy the most demanding applications. End-users

have the option of selecting preprogrammed software templates, programming

through an HMI or R86 Teach Pendant, or utilizing RT-ToolBox3 with RT

VisualBox software to create programs. Each programming option offers

distinct advantages and benefits by catering to various programming

knowledge levels.

HIGH PERFORMANACE IN A SMALL FOOTPRINT

Embedded FX5 PLC delivers superior functionality and

flexibility

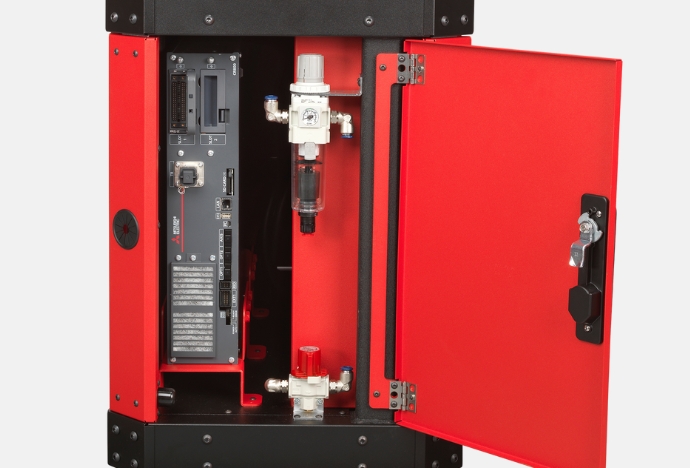

Flexible and intuitive - ARIA’s base has a small

footprint that enables use in confined spaces. ARIA is powerful enough to

act as a stand-alone system, or it can be easily implemented into an

existing automation cell. ARIA utilizes our powerful FX5 PLC to enable

functionality and flexibility for the most demanding applications.

ARIA’s base houses all critical components required for operation,

including: CR800 control, FX5 PLC, HMI, power supply, and air regulatio.

KEY ROBOT OPTIONS

All robot options can be found in our technical specification guide.

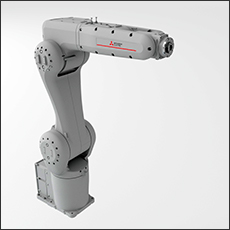

RV-CR SERIES

Slim and compact robot offering a high level of utility and design in a

cost-effective package. Perfect all around, versatile robot.

RV-FR SERIES

Available in a variety of reaches, payloads, and protection ratings

(including Food Grade/Chemical Resistant) for jobs that require it.

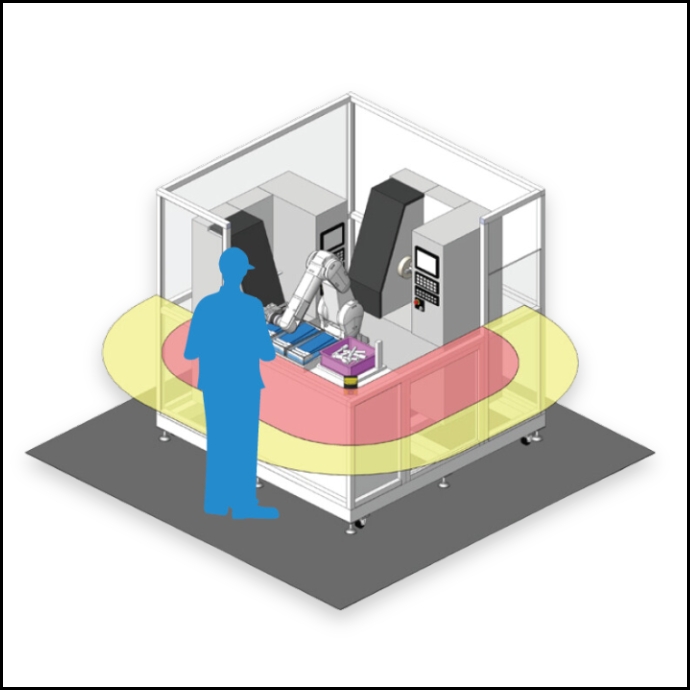

ASSISTA COBOT

Our industrial Cobot combines the safety and ease-of-programming of a

collaborative robot with the durability and higher cycle speeds of

industrial robots.

SCARA

Our SCARA robots are ready to be the high speed robotic solution for even

the most demanding of applications.

ARIA ACCESSORIES

All robot options can be found in our technical specification guide.

Preprogrammed Software Packages

For users wanting access to preprogrammed software on the Standard Base,

the optional HMI provides access to preprogrammed software packages and

allows users to manually jog, teach and monitor robot and system status.

RT Toolbox3

Support the life cycle of your system, including programming and editing,

scope of operations, tact time, debugging prior to startup, and monitoring

of robot conditions and malfunctions during operations

MELFA Works

Simulate robot production systems on SolidWorks and output the data of

processing paths on workpieces.

Force Sensor

Assembly/processing tasks are performed in the same manner as a human

being, while sensing the force that is applied to the gripper.

R86TB Teach Pendant

High-performance teach pendant for improved operability. Handles processes

from setup to maintenance, reducing time and cost.

GT25 Handy HMI

For users wanting access to preprogrammed software on Machine Tool base,

the GT25 Handy HMI provides access to preprogrammed software packages and

allows users to manually jog, teach and monitor robot and system status

via a lightweight, portable and high-resolution HMI.

Ready to maximize your system performance?

-

Inquiries

-

Select

& Quote -

Share

-

Partners