Industries

Machine Tending Automation Solutions

Industry Solution: Machine Tending

Mitsubishi Electric is a world-leading and trusted CNC and Automation supplier with unique experience in all facets of CNC Machining, including service. The quality and performance of our CNCs have resulted in loyal, long-time customers. We are proud to continue our support of the Machine Tool industry with cost-effective robotic machine tending automation solutions to address common challenges faced in the industry. Mitsubishi Electric's robotic products are among the fastest and most durable available, resulting in flexible systems capable of high production rates and low downtime. Our technologies also support integration with machine tending IIoT solutions, enabling smarter operations.

Mitsubishi Electric can be your trusted advisor in machine tending. Whether it is your first robotic machine tending project, or your 100th, our machine tending solutions help to increase production rates while achieving a good return on your investment. We offer adaptable machine tending stations to suit any shop floor configuration.

- Industry Challenges

- Solutions

- Free ROI Estimator Tool

- Machine Tending Overview

- White Paper: How to Achieve Success in Your First Robotic Machine Tending Project

- Case Study: Small Machine Shop Triples Production Output

- Case Study: Solution Provides Opportunity for Hours of Unattended Run Time

- On-Demand Webinar: Achieving Success in Your First Robotic Machine Tending Project

- Frequently Asked Questions

- Resources

Industry Challenges

-

Skilled Workforce Shortage

With over 2 million open positions left vacant due to the skills shortage, automated processes become more necessary than ever. For repetitive tasks, a robot can provide 24/7 machine tending support, leaving your staff available to accomplish more rewarding and productive tasks. With machine tending automation, manufacturers can bridge the workforce gap and boost productivity.

-

Staying Competitive with High-Production Rates

For businesses being asked to produce more products quickly, automated machine tending can maximize the output of your CNC machines by reducing part exchange time and increasing hours of CNC operation. Implementing machine tending solutions helps companies remain agile in meeting production demands.

-

Implementation Support

Mitsubishi Electric Automation takes the hassle and risk out of implementing a new automation system. With an extensive, nationwide support and service network, we ensure your system works to your expectations. Our specialists will help align your investment with the right machine tending tools, machine tending IIoT solutions, and scalable machine tending workstations.

Solutions

-

Robot & Stand for Large Machine Tending Applications

LoadMate Plus™ is designed to automate the machine tending process for larger applications. It can be customized for efficient use of your floor space and can be moved around between machines as jobs require. As part of our integrated machine tending automation suite, it supports seamless connectivity with existing equipment.

-

Compact Robot Base for Machine Tending Applications

ARIA (Automated Robotic Industrial Assistant) is a cost-effective automated machine tending robot and cell. It is specifically designed for Mill, and Lathe tending, but can be used with a wide variety of CNC types. ARIA comes standard with a compact PLC and high-performance teach pendant, making it one of our most cost effective and efficient machine tending products and a key component in flexible machine tending solutions.

-

Custom Turnkey Solution

Mitsubishi Electric Automation is equipped with the experience and knowledge to build a custom turnkey solution to meet the exact needs of an application. Through high-performance controls and robotics, custom solutions are built-to-last and deliver the productivity required to stay competitive in machining. These turnkey systems incorporate our durable automation components and data-driven machine tending IIoT solutions.

Testimonials & Tools

Estimate your ROI for Deploying Robotic Machine Tending Solutions

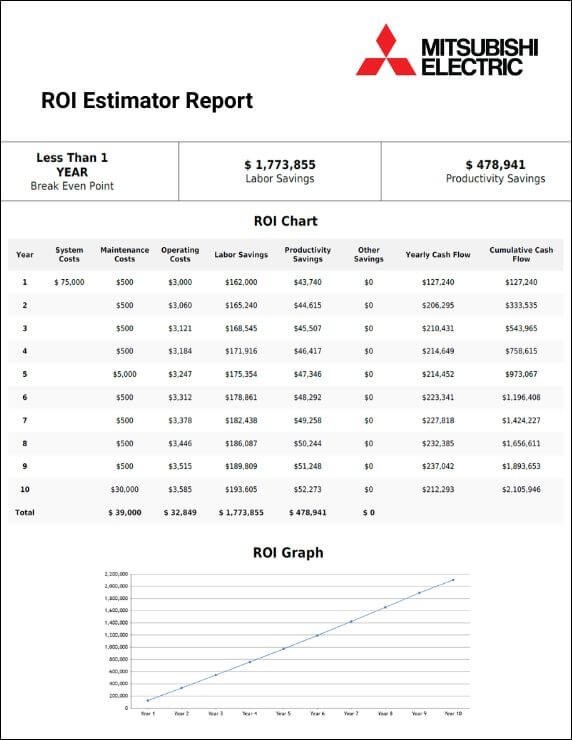

Whether it is your first robotic automation project or your 100th, investing in new technologies can feel intimidating. Understanding your return on investment (ROI) can help navigate the next steps in your automation implementation journey. This estimator demonstrates the substantial cost-saving potential of integrating robots into your operations over the lifespan of a project, particularly with scalable machine tending automation and plug-and-play machine tending solutions.

Solutions Overview for Robotic Machine Tending

See the solutions overview to learn more about our history and experience in the machine tool industry, with solutions available to you for robotic machine tending, including portable and dedicated machine tending stations with machine tending IIoT and other advanced technologies.

White Paper - How to Achieve Success in Your First Robotic Machine Tending Project

The skills gap is growing. Turnover rates are staggering. Machines are left idle. It's time for a solution that supports you today and is future-proof for tomorrow. In this guide, "How to achieve success in your first robotic machine tending project," we arm you with the knowledge, resources, and support you need to feel confident in your decision to invest in a new solution, including smart machine tending solutions and connected machine tending IIoT solutions.

Small Machine Shop Triples Production Output with Robotic Machine Tending

When TL Aerotek was receiving more orders than they could keep up with, they turned to Mitsubishi Electric Automation for an automated machine tending solution. LoadMate Plus delivered easy programming and precision to reach new levels of productivity through intelligent machine tending automation.

Turnkey Machine Tending Solution Provides Opportunity for Hours of Unattended Run Time

World Wide Fittings (WWF) was looking for a turnkey automation solution to help them continue to manufacture domestically. A robotic automation solution from Mitsubishi Electric streamlined their operations, while boosting competitive edge with integrated machine tending stations featuring flexible and durable automation components.

On Demand Webinar - How to Approach Your First Robotic Machine Tending System

Frequently Asked Questions

Does cutting fluid harm either the robot or the gripper?

- Our robots for machine tending are either IP65 or IP67 rated, meaning they are built to withstand these harsh environments. For complete systems, we select grippers that are designed for these types of environments.

How often will I need to reprogram the robot or reteach the points?

- As long as the relationship between the robot and the spindle remains constant, you won’t need to reprogram. Adding new parts rarely requires reprogramming, but moving either the robot or CNC, or adding something new to the cycle, will require the program to be modified.

My shop gets hot in the summer and cold in the winter.

Will this bother the robot?

- Most industrial robots can operate in ambient temperatures ranging from 32° to 112°F. We rarely see shop floors outside this range, but we will work with you to implement supplemental temperature control if your shop requires it.

How do you address the hurdles of high mix, low volume production?

Will they work with most or all CNC machines?

- High-mix/low-volume applications are challenging, but Mitsubishi Electric Automation has years of experience with them. We’ll work with you to design a system that addresses your parts mix with minimal changeover.

How do I plan & execute a successful robotic machine tending project?

- To be successful, it's important that you have a clear understanding of your operational goals, equipment compatibility, and automation strategy. Our comprehensive whitepaper, “How to achieve success in your first robotic machine tending project”, walks you through each critical phase, from initial planning and risk assessment to deployment and optimization.

Ready to Connect With Mitsubishi Electric Automation?

-

Inquiries

-

Select

& Quote -

Share

-

Partners