Industries

Smart Crane & Hoist Solutions

Your Partner for Smart Cranes & Hoists

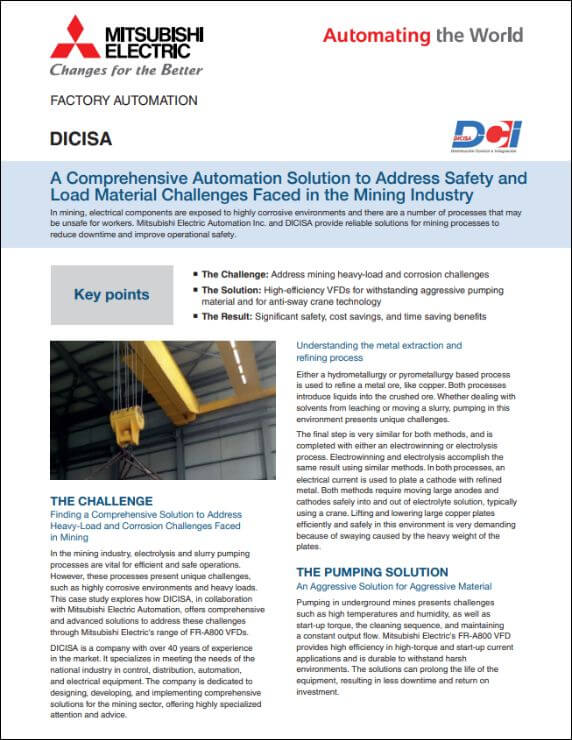

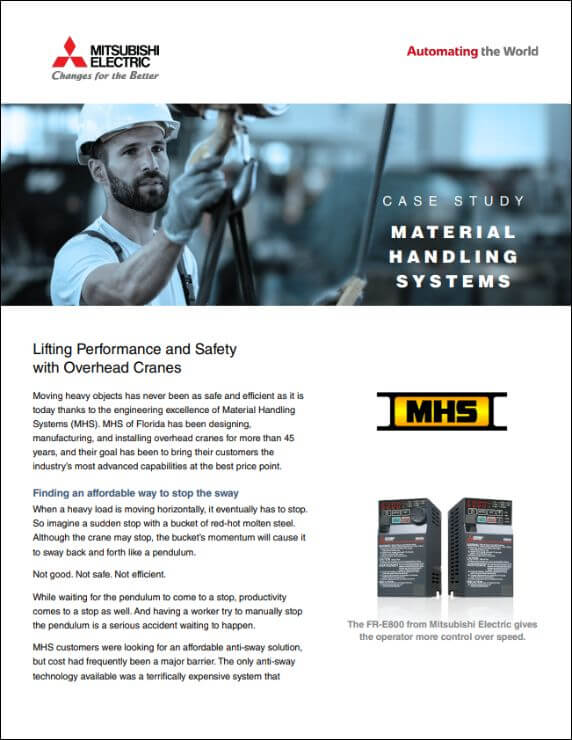

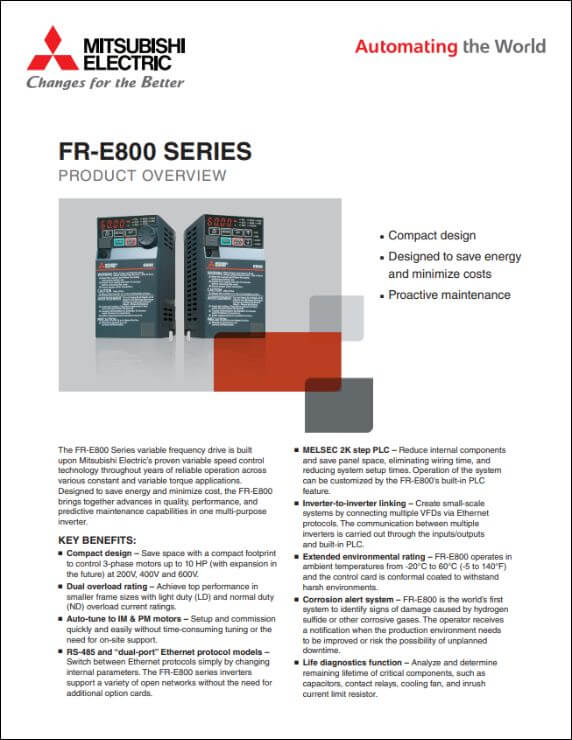

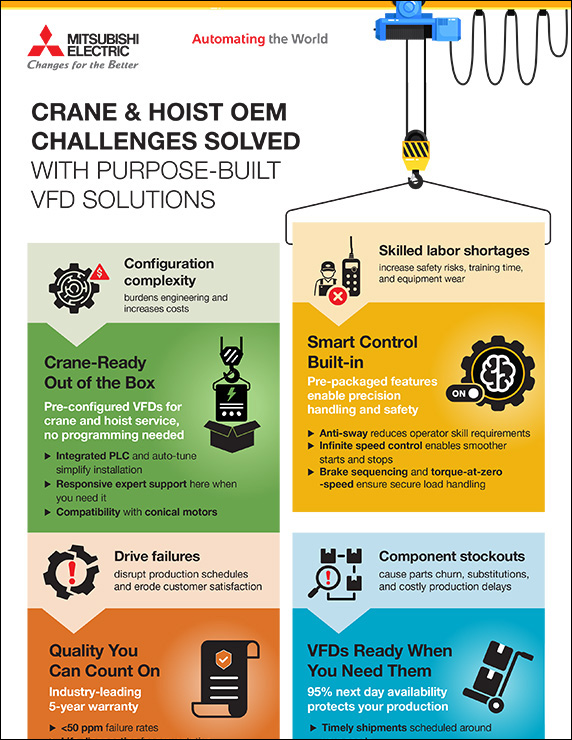

Smart cranes & hoists demand more than traditional contactor controls. Our advanced VFD solutions deliver precise motion, integrated safety, and energy efficiency. This helps OEMs and end users build lifting systems that are safer, more productive, and ready for the future of material handling.

Safe and Precise Solutions for Crane & Hoist

By Partnering with Mitsubishi Electric Automation, You Can Expect:

-

Smart and Durable Products

-

Reliable Delivery and Supply Chains

-

Comprehensive Support

More Information

Frequently Asked Questions

Why should I upgrade my crane controls to VFDs?

- VFDs improve safety, precision, and uptime. They provide smooth starts/stops, reduce hook sway, extend brake life, and meet OSHA/ASME/CMAA compliance. Upgrades often pay for themselves through reduced maintenance and faster load handling.

What about my existing brakes and mechanical components?

- VFDs extend brake life by sequencing brake lift after torque proving and controlled closing. This reduces shock loads and mechanical wear, often doubling brake service intervals.

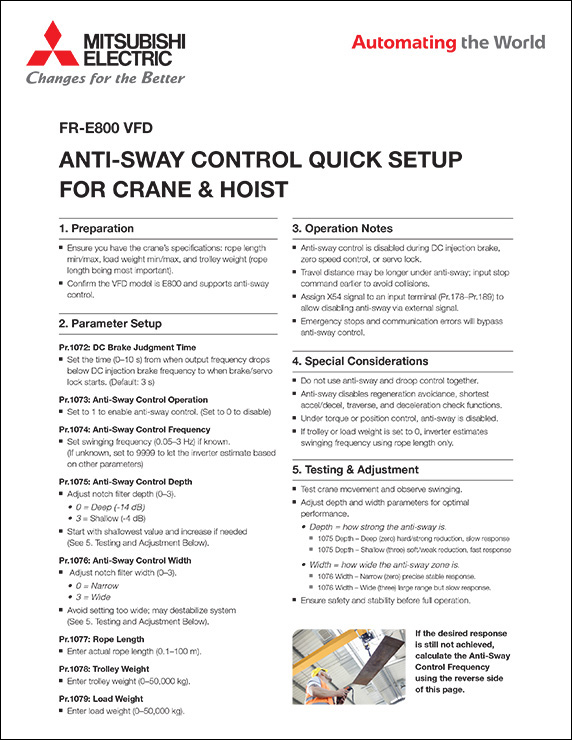

Can VFDs reduce hook sway?

- Yes. Crane-specific anti-sway algorithms and smooth ramp profiles minimize load swing, improving operator confidence and reducing cycle times.

Will operators need retraining?

- Minimal. Pendant layouts can remain the same and add features like 2-step infinite speed for better control. A short familiarization session is usually enough.

Do VFDs help with energy savings?

- Yes. Drives reduce resistor heat and can include regenerative options for high-duty cranes. Energy savings are modest for small cranes but add up over time.

Can your VFD handle conical rotor motors?

- Yes. Our VFDs are designed to work with conical rotor motors used in cranes and hoists, ensuring smooth starts, proper brake control, and reliable performance.

Ready to Connect With Mitsubishi Electric Automation?

-

Inquiries

-

Select

& Quote -

Share

-

Partners