Industries

Electronics Manufacturing

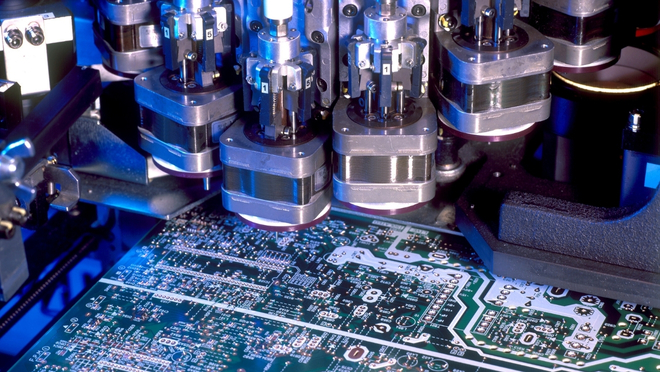

Despite the high-tech, state-of-the-art appeal of modern electronic devices, a large part of their manufacture is still performed manually. A major challenge of this elaborate and complex work is to reduce human error by automating part loading, surface implementation, PCB and unit assembly, as well as shipment. Issues that occur throughout the production line include process stops due to parts shortages, complicated machine adjustments, incorrect assembly during high-mix, low-volume production and more.

Mitsubishi Electric's e-F@ctory provides industrial automation robots equipped with force sensors and work support systems to address each of these issues. They can provide advance notification of shortages in the parts warehouse. They can make complicated adjustments to machine workpieces of various shapes. They can optimize unit assembly to support fluctuating production loads. And they can simplify equipment startup and fully automate inspection.

More Information

Ready to Connect With Mitsubishi Electric Automation?

-

Inquiries

-

Select

& Quote -

Share

-

Partners